Precision Thermo Gravimetric Analyzer For Coating

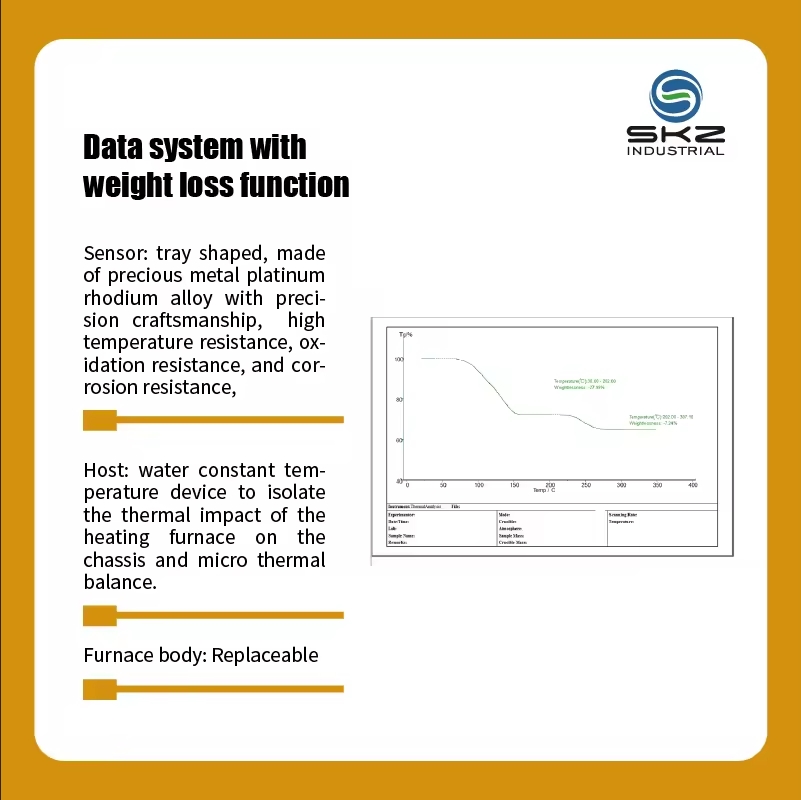

1. In the heating stage of the furnace body, a double-row winding of high-temperature wire is employed. This design not only diminishes interference but also exhibits enhanced resistance to high temperatures, ensuring more stable and reliable operation. 2. The sensor tray is crafted from alloy wire with meticulous precision. It possesses excellent anti-oxidation, high-temperature resistance, and corrosion resistance properties, guaranteeing the accuracy and durability of the sensor in various environments. 3. The power supply and circulating heat dissipation components are separated from the core unit. This separation effectively minimizes the influence of heat and vibration on the micro-thermal balance, thereby enhancing the measurement precision and stability of the instrument. 4. The equipment features a top-opening structure, which offers convenient operation for users. It simplifies the process of sample loading and unloading, as well as any necessary adjustments or maintenance procedures. More details, click here.

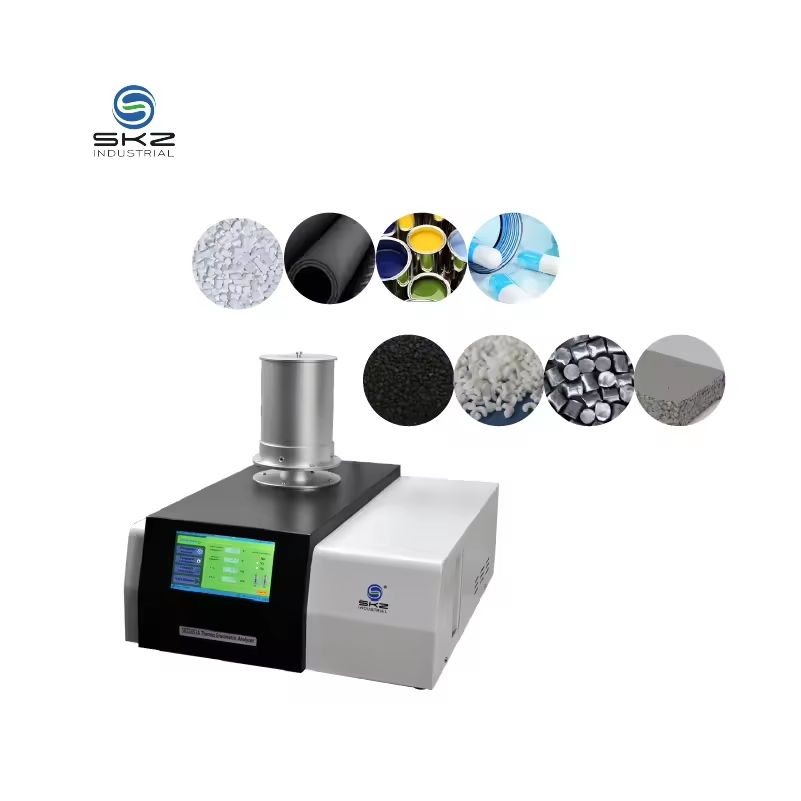

SKZ1053 Automatic Thermo Gravimetric Analysis (TGA) Pricing and Features Thermo gravimetric analysis (TGA) is a technique utilized to monitor the variation in sample quality with respect to temperature or time during the processes of heating and maintaining a constant temperature. Its primary objective is to investigate the thermal stability and composition of materials. This method finds extensive application in the research and development, process optimization, and quality control of diverse materials such as plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal substances, and composite materials. Controller and Software Advantages 1. The system incorporates an imported ARM processor, which enables a rapid sampling speed and an even faster processing rate. This enhanced processing capability allows for more efficient data acquisition and analysis, ensuring that the TGA instrument can accurately capture and interpret the changes in sample mass as the temperature varies. 2. A four-channel sampling AD is employed to collect both the TG signal and the temperature T signal. This multi-channel sampling approach provides a more comprehensive and accurate representation of the thermal behavior of the sample. By simultaneously monitoring multiple aspects of the sample's response to temperature changes, the instrument can offer detailed insights into the material's properties and its transformation during the heating process. 3. For heating control, a PID (Proportional-Integral-Derivative) algorithm is utilized, ensuring precise control over the temperature. This advanced control mechanism allows for multi-stage heating and stable temperature maintenance. The PID algorithm continuously adjusts the heating power based on the difference between the desired temperature and the actual temperature, minimizing temperature overshoot and fluctuations. This level of temperature control is crucial for obtaining reliable and reproducible TGA results, especially when dealing with materials that exhibit sensitive thermal behavior. 4. The software and the instrument communicate via USB two-way communication, enabling seamless remote operation. Through this connection, users can fully control the instrument's parameter settings, initiate and stop operations, all from a computer software interface. This remote operation capability offers enhanced convenience and flexibility, allowing users to manage the TGA analysis without being physically present near the instrument. It also facilitates integration with automated laboratory systems and remote monitoring, which is particularly beneficial in industrial and research settings where multiple instruments may be operated simultaneously. 5. The instrument features a 7-inch full-color 24-bit touch screen, providing a superior man-machine interface. This high-resolution touch screen allows for easy navigation and interaction with the instrument's functions. Notably, TG calibration can be conveniently performed directly on the touch screen. Users can input calibration parameters and initiate the calibration process with a simple touch, streamlining the calibration procedure and ensuring the accuracy of the TGA measurements. The intuitive interface also makes it easier for operators to monitor the progress of the analysis, view real-time data, and access various instrument settings and functions, enhancing the overall user experience and efficiency of the TGA analysis process.

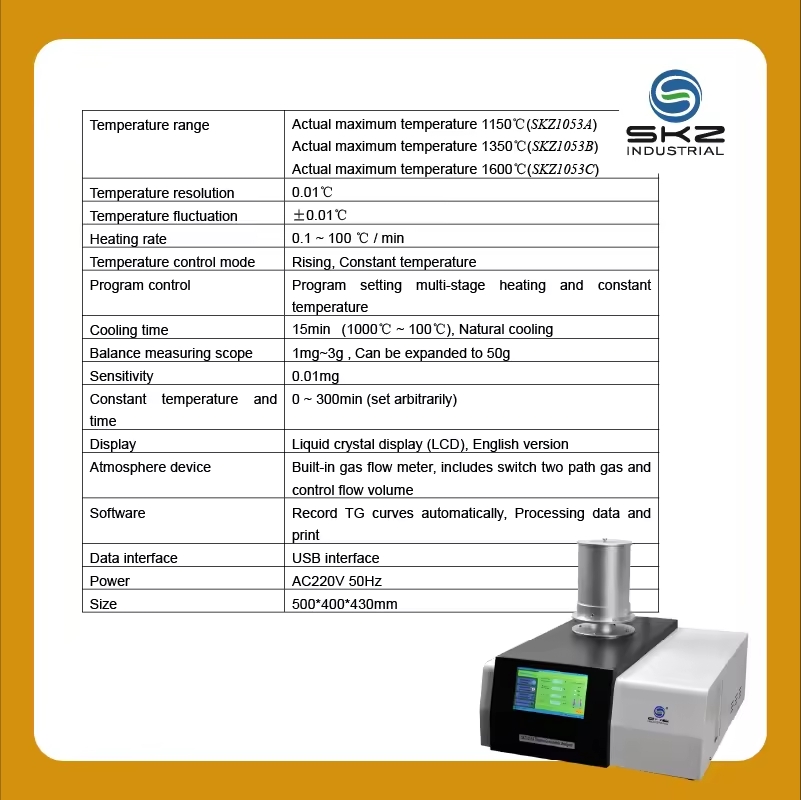

Technical parameters:

Temperature range | Actual maximum temperature 1150℃(SKZ1053A) Actual maximum temperature 1350℃(SKZ1053B) Actual maximum temperature 1600℃(SKZ1053C) |

Temperature resolution | 0.01℃ |

Temperature fluctuation | ±0.01℃ |

Heating rate | 0.1 ~ 100 ℃ / min |

Temperature control mode | Rising, Constant temperature |

Program control | Program setting multi-stage heating and constant temperature |

Cooling time | 15min (1000℃ ~ 100℃), Natural cooling |

Balance measuring scope | 1mg~3g , Can be expanded to 50g |

Sensitivity | 0.01mg |

Constant temperature and time | 0 ~ 300min (set arbitrarily) |

Display | Liquid crystal display (LCD), English version |

Atmosphere device | Built-in gas flow meter, includes switch two path gas and control flow volume |

Software | Record TG curves automatically, Processing data and print |

Data interface | USB interface |

Power | AC220V 50Hz |

Size | 500*400*430mm |

1.Provide different specifications of voltage,plugs according to customers'needs.USB communication interfacestrong versatility,reliable and uninterrupted communication,supports self-recovery connection function

2.Automatically switch the two-channel atmosphere flow,fast switching speed and short stabilization

4.Adopt top-opening structure,easy to operate.It is difficult to move the furnace body up to place the sample,and it is easy to damage the sample rod.

5.The heating part of the furnace body adopts double-row winding of high temperature wire,which reducesinterference and is more resistant to high temperature.

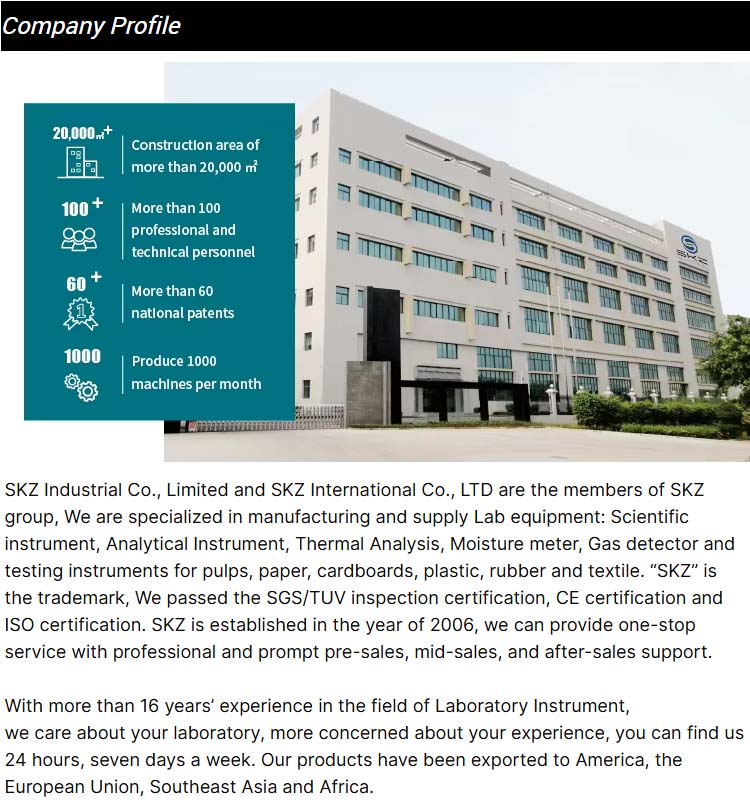

SKZ Industrial Co., Limited and SKZ International Co., LTD are integral members of the SKZ group. We have carved a niche for ourselves in the manufacturing and supply of a wide range of high-quality lab equipment. Our product portfolio encompasses Scientific instruments, Analytical Instruments, Thermal Analysis equipment, Moisture meters, Gas detectors, as well as testing instruments designed specifically for pulps, paper, cardboards, plastics, rubber, and textiles. The "SKZ" brand is our trademark, symbolizing our commitment to excellence. We have successfully obtained several prestigious certifications, including SGS/TUV inspection certification, CE certification, and ISO certification. These certifications are a testament to our adherence to strict international quality and safety standards. Established in 2006, SKZ has amassed over 16 years of rich and valuable experience in the Laboratory Instrument field. We take pride in our ability to offer a comprehensive one-stop service, supported by a team of professionals who provide prompt and efficient pre-sales, mid-sales, and after-sales support. Our dedication to customer satisfaction extends beyond just providing quality products. We understand the importance of your laboratory operations and are deeply concerned about your overall experience. That's why we are available 24/7 to address any queries or concerns you may have. Thanks to our unwavering commitment to quality and customer service, our products have found their way into numerous international markets. We have successfully exported our equipment to the Americas, the European Union, Southeast Asia, and Africa, earning the trust and loyalty of customers worldwide.