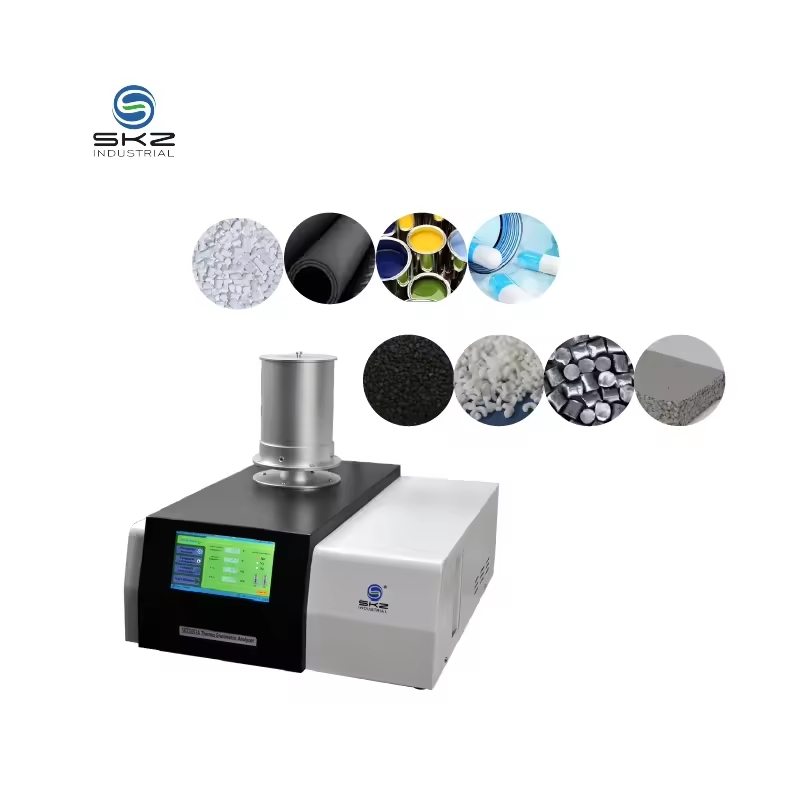

Automatic 0.01℃ Thermo gravimetric analyzer

1. The heating phase of the furnace physique adopts double-row winding of excessive temperature wire, which reduces interference and is greater resistant to excessive temperature.

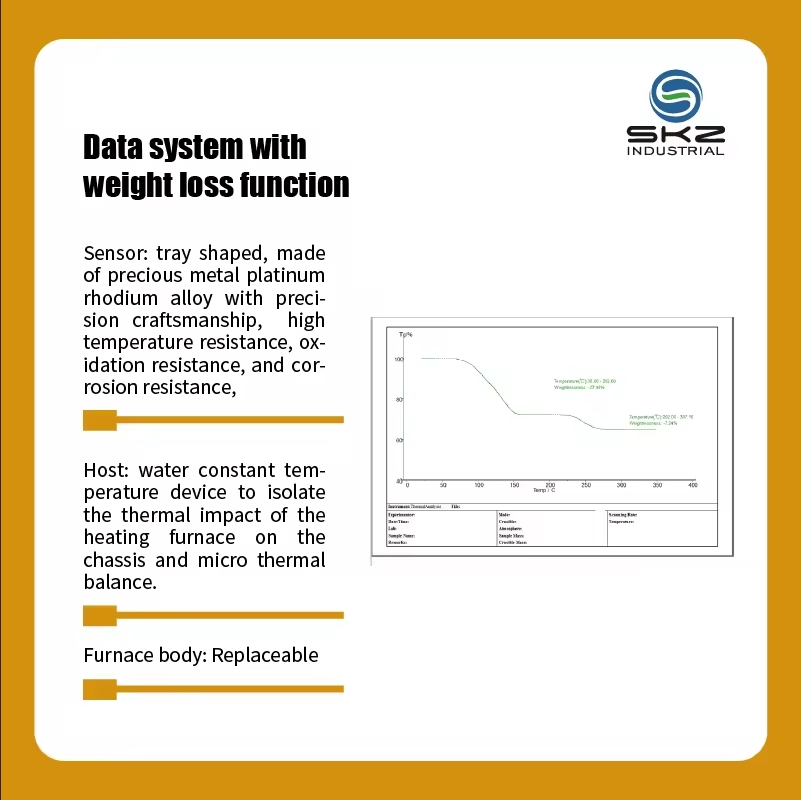

2. The tray of the sensor is made of alloy wire, made with precision, anti-oxidation, excessive temperature resistance and corrosion resistance.

3. The strength furnish and circulating warmth dissipation section are separated from the essential unit to minimize the impact of warmness and vibration on the micro-thermal balance.

4. It adopts top-opening structure, which is convenient to operate.

5. The host adopts to isolate the thermal impact of the heating furnace physique on the chassis and the micro-thermal balance.

More details, pls click. Youtube link

SKZ1053 Automatic Thermo GravimetricAnalysis Tga Price

Thermo gravimetric evaluation (TG, TGA) is to examine the exchange of pattern exceptional with temperature or time in the technique of heating and regular temperature, the reason is to learn about the thermal balance and composition of the material.

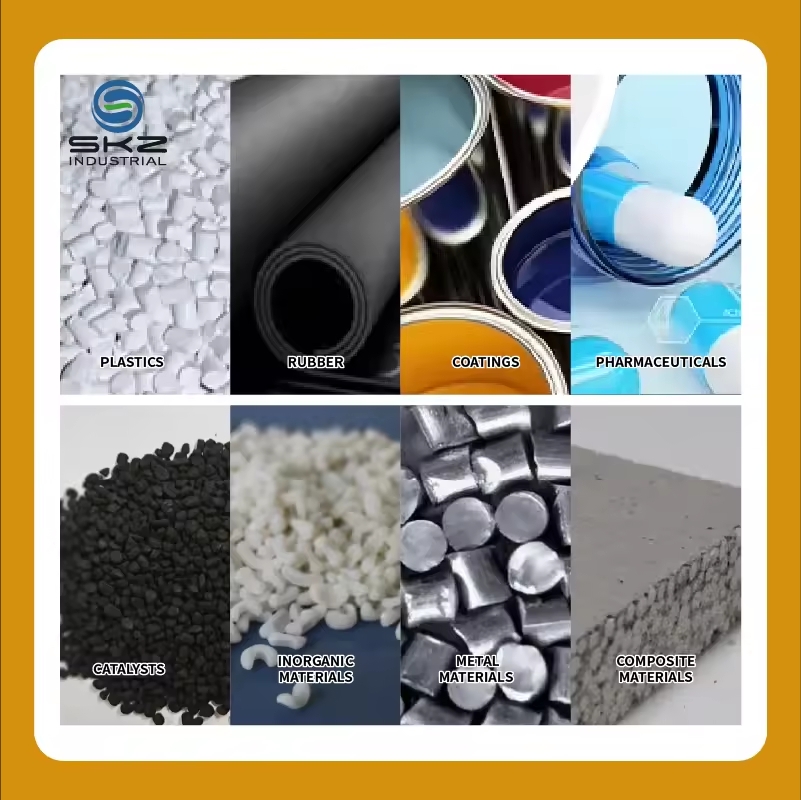

Widely used in the lookup and development, procedure optimization and excellent manage of plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, steel substances and composite substances

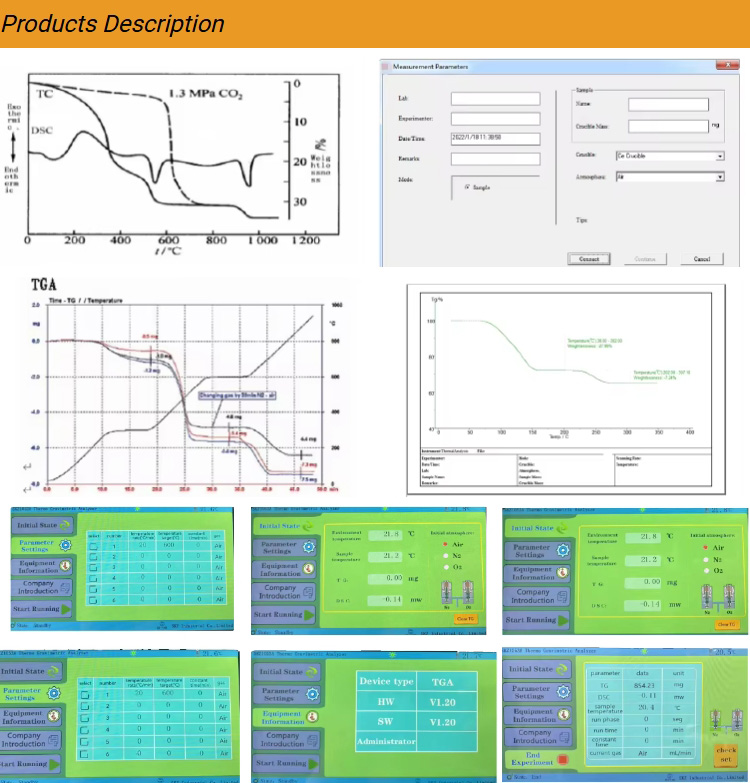

Controller and software program advantages:

1. Using imported ARM processor, sampling speed, processing pace is faster.

2. Four-channel sampling AD collects TG sign and temperature T signal.

3. Heating control, the usage of PID algorithm, particular control. Multi-stage heating and steady temperature

4. The USB two-way conversation is adopted between the software program and the instrument to thoroughly understand faraway operation. The parameter putting of the instrument and the operation and give up of the instrument can be carried out thru the laptop software.

5. 7-inch full-color 24bit contact screen, higher man-machine interface. TG calibration can be finished on the contact display screen

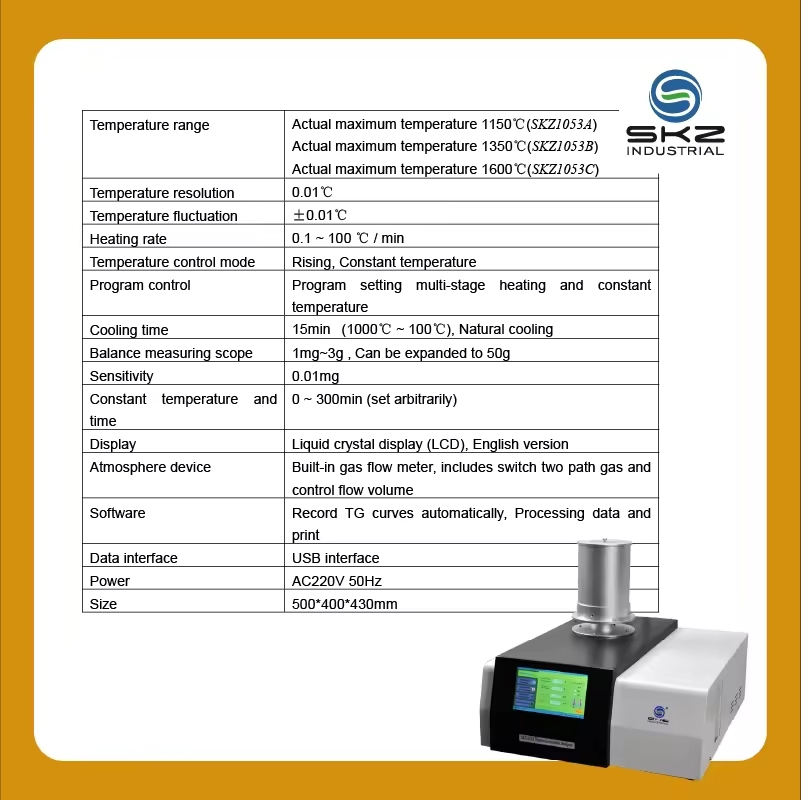

Technical parameters:

Temperature range | Actual maximum temperature 1150℃(SKZ1053A) Actual maximum temperature 1350℃(SKZ1053B) Actual maximum temperature 1600℃(SKZ1053C) |

Temperature resolution | 0.01℃ |

Temperature fluctuation | ±0.01℃ |

Heating rate | 0.1 ~ 100 ℃ / min |

Temperature control mode | Rising, Constant temperature |

Program control | Program setting multi-stage heating and constant temperature |

Cooling time | 15min (1000℃ ~ 100℃), Natural cooling |

Balance measuring scope | 1mg~3g , Can be expanded to 50g |

Sensitivity | 0.01mg |

Constant temperature and time | 0 ~ 300min (set arbitrarily) |

Display | Liquid crystal display (LCD), English version |

Atmosphere device | Built-in gas flow meter, includes switch two path gas and control flow volume |

Software | Record TG curves automatically, Processing data and print |

Data interface | USB interface |

Power | AC220V 50Hz |

Size | 500*400*430mm |

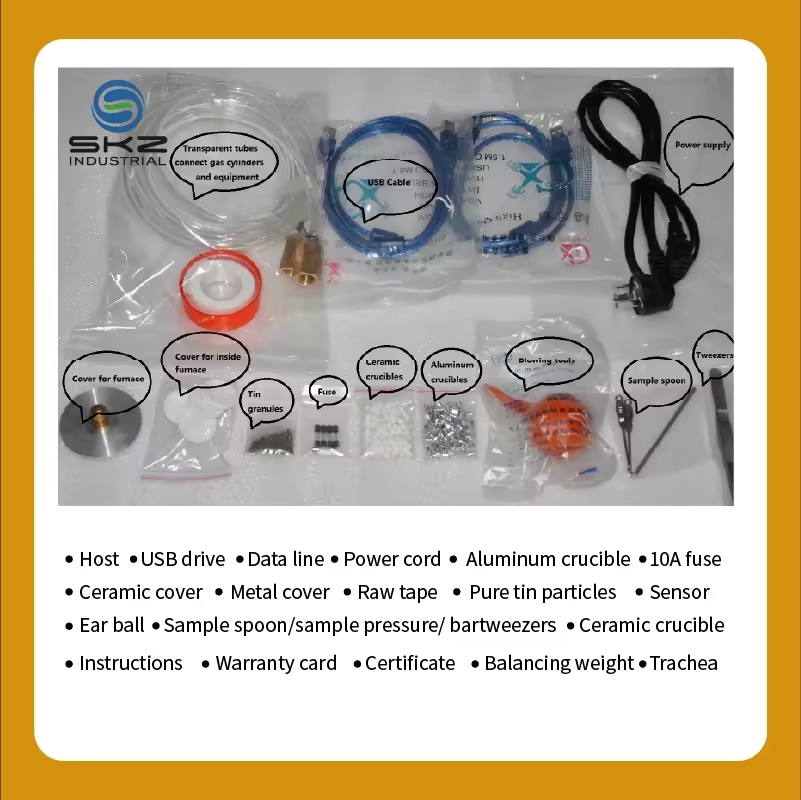

1.Provide different specifications of voltage,plugs according to customers'needs.USB communication interfacestrong versatility,reliable and uninterrupted communication,supports self-recovery connection function

2.Automatically switch the two-channel atmosphere flow,fast switching speed and short stabilization

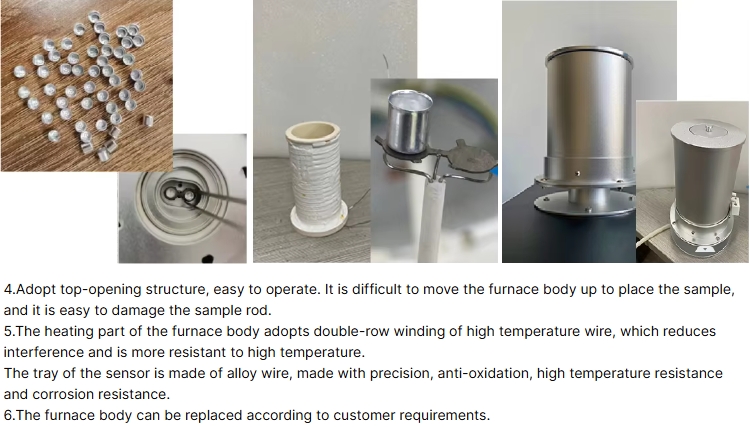

4.Adopt top-opening structure,easy to operate.It is difficult to move the furnace body up to place the sample,and it is easy to damage the sample rod.

5.The heating part of the furnace body adopts double-row winding of high temperature wire,which reducesinterference and is more resistant to high temperature.

Application scenarioscatalysts

inorganic

metal

compositematerials

materials

materialsplastics

rubber

coatings

pharmaceuticals

We welcome customers to contact us for futurebusiness relationships and mutual success!

After-sales service

1.Within a year,if there are

quality issues,we can provide

free technical support and

repair,as well as shipping costs

2.After one year,we still providetechnical support free charge,

including software update

service,and if need to returnrepair,

user need to bear the repair

accessory charge and round-trip

shipping costs.

Welcome to contact me:

sales7@skzindustrial.com(email)

+86 15508650267(WhatsApp)