Tga Thermogravimetric Analysis

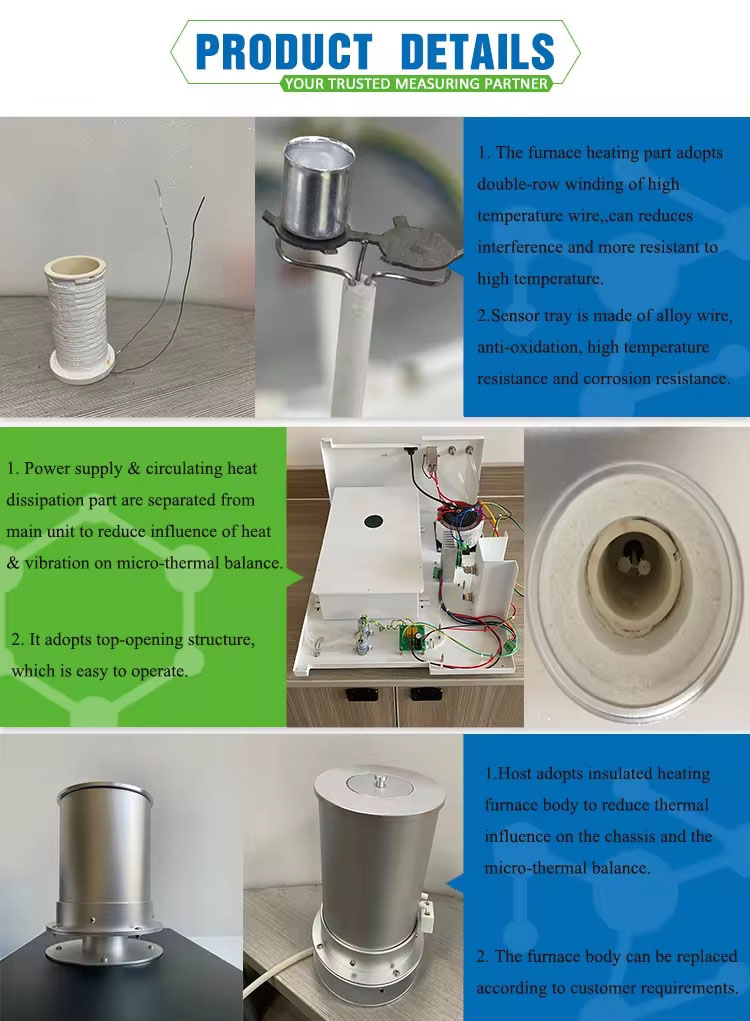

1. Double-row winding of precious metal nickel-cadmium alloy wire, which lowers interference and is more resistant to high temperatures, heats the furnace body.

2. The tray sensor's high temperature, oxidation, and corrosion resistance come from the precious metal alloy wire used to make it.

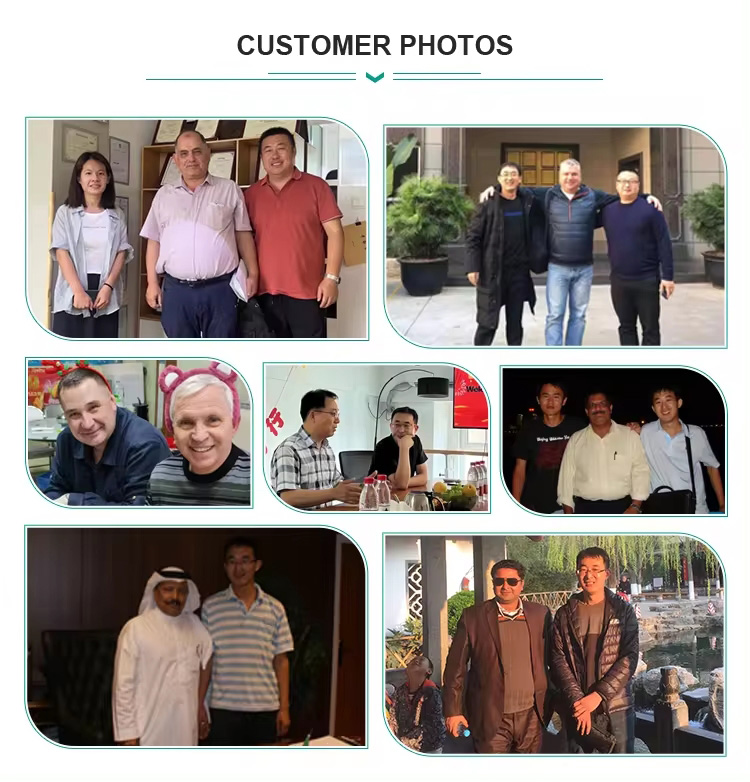

3. To lessen the impact of heat and vibration on the micro-thermal balance, the power supply and circulating heat dissipation component are isolated from the main machine.

4. Adopt top-opening structure, easy to operate. The sample rod is easily damaged, and it is challenging to raise the furnace body to position the sample.

Follow us on Facebook and Youtube.More Thermal Analysis,click here.

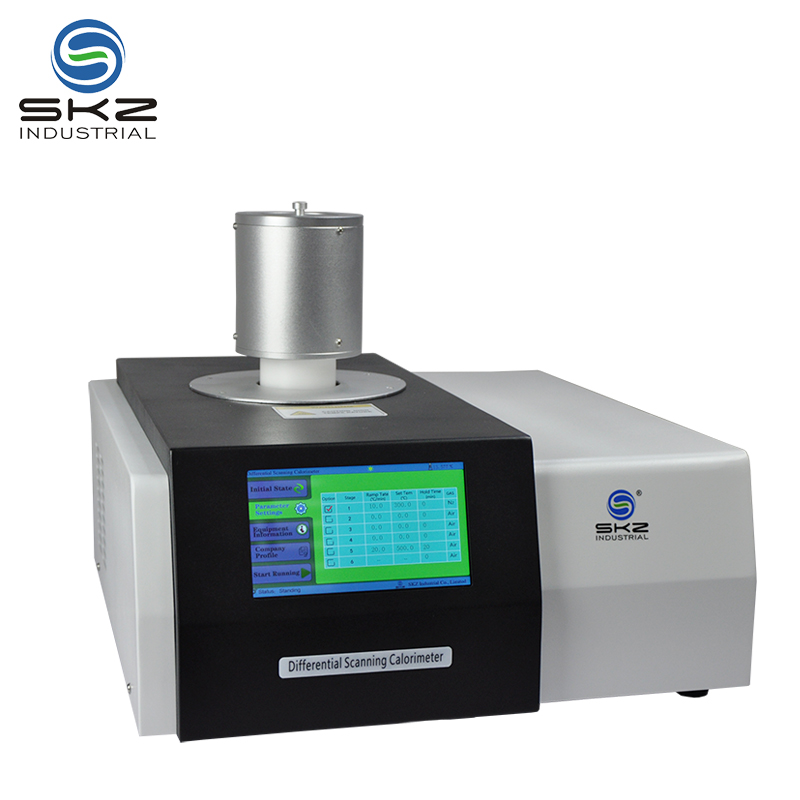

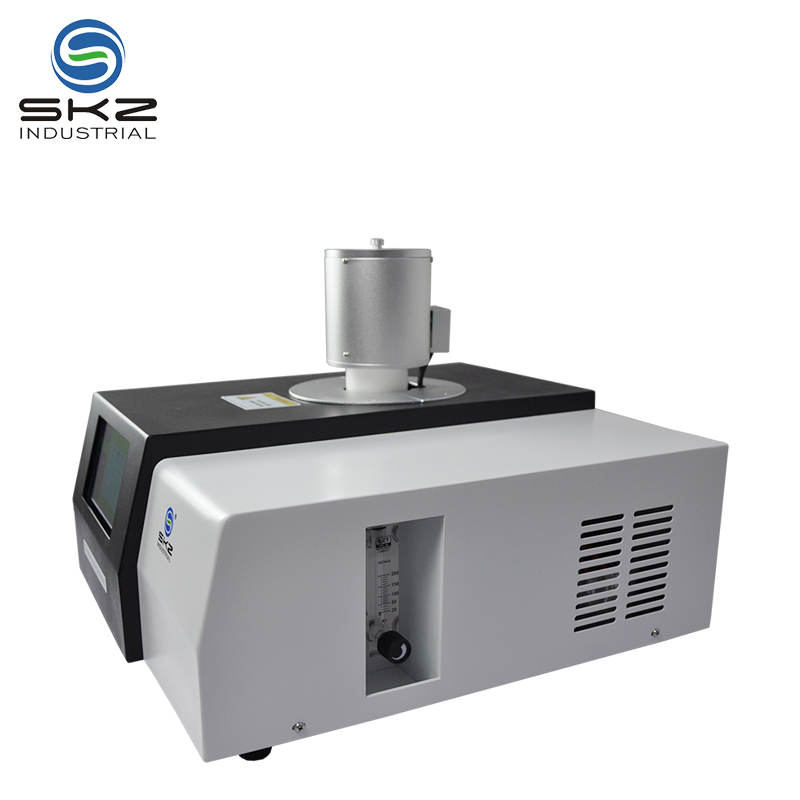

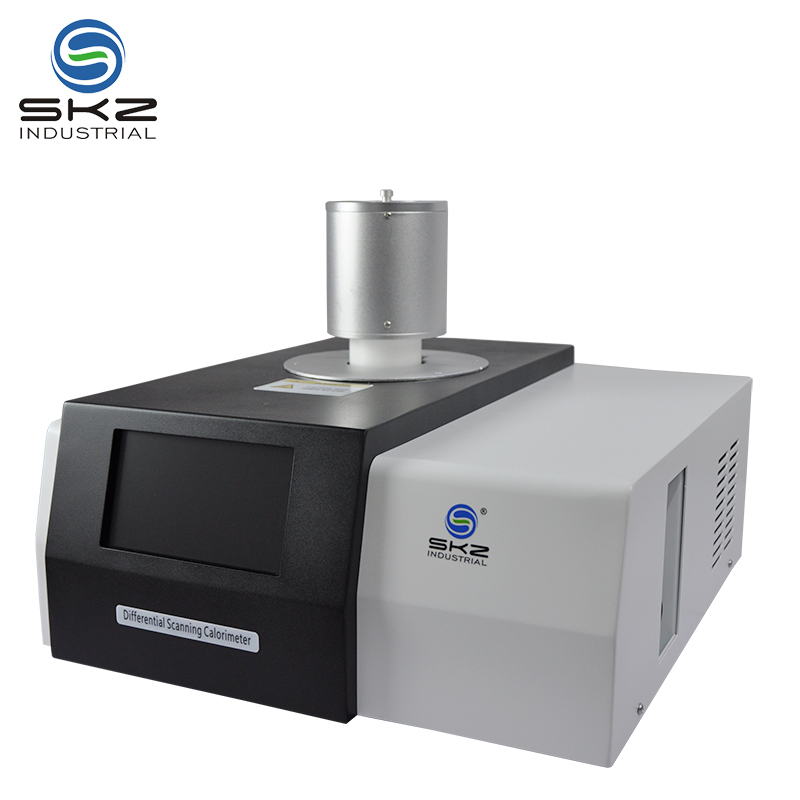

SKZ1053 Tga Thermogravimetric Analysis

Thermogravimetric analysis (TG, TGA) is used to track changes in sample quality over time or at different temperatures while heating a material to investigate its composition and thermal stability.

extensively employed in the development, manufacturing, testing, and quality assurance of polymers, rubber, coatings, medicines, catalysts, inorganic, metal, and composite materials.

Applications:moisture and volatiles, reaction kinetics, decomposition process, adsorption and desorption, oxidation and reduction, quantitative analysis of components, and additions and fillers.

Advantages of the structure:

1.Double-row winding of precious metal nickel-cadmium alloy wire, which lowers interference and increases resistance to high temperatures, heats the furnace body.

2.The tray sensor's high temperature, oxidation, and corrosion resistance come from the precious metal alloy wire used to make it.

3.To lessen the impact of heat and vibration on the micro-thermal balance, the power supply and circulating heat dissipation component are isolated from the main machine.

4.Adopt a top-opening design that is simple to use. It is challenging to raise the furnace body in order to position the sample, and it is simple to break the sample rod.

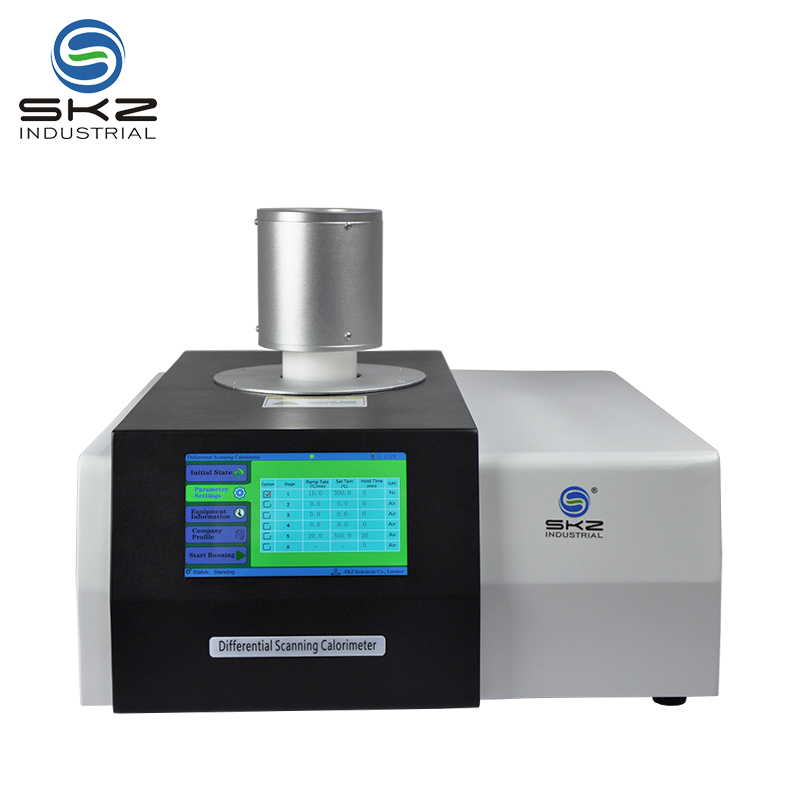

5.The host makes use of the micro-thermal balance and heat insulation provided by the heating furnace body to the chassis.

6.The furnace body can be changed in accordance with what the client wants.

Advantages of controllers and software:

1. Processing and sampling speeds are faster when using an imported ARM CPU.

2. Temperature T signal and TG signal are collected by four-channel sampling AD.

3. PID algorithm-based precise regulation of heating. Heating in stages and maintaining a steady temperature

4. In order to completely achieve remote operation, the software and the instrument employ USB two-way communication. The computer program can be used to establish the instrument's parameters as well as to operate and stop the device.

A 7-inch touch panel with 24bit color and a superior man-machine interface. Touch screen calibration is possible for TG.

Temperature range | Actual maximum temperature 1150℃(SKZ1053A) Actual maximum temperature 1350℃(SKZ1053B) Actual maximum temperature 1600℃(SKZ1053C) |

Temperature resolution | 0.01℃ |

Temperature fluctuation | ±0.01℃ |

Heating rate | 0.1 ~ 100 ℃ / min |

Temperature control mode | Rising, Constant temperature |

Program control | Program setting multi-stage heating and constant temperature |

Cooling time | 15min (1000℃ ~ 100℃), Natural cooling |

Balance measuring scope | 1mg~3g , Can be expanded to 50g |

Sensitivity | 0.01mg |

Constant temperature and time | 0 ~ 300min (set arbitrarily) |

Display | Liquid crystal display (LCD), English version |

Atmosphere device | Built-in gas flow meter, includes switch two path gas and control flow volume |

Software | Record TG curves automatically, Processing data and print |

Data interface | USB interface |

Power | AC220V 50Hz |

Size | 500*400*430mm |