Five points Heat Seal Tester

Five-point heat-seal Tester (also known as gradient heat seal tester) can be used to determine the heat sealing temperature range , suitable packaging speed, and heat sealing pressure of the plastic film substrate, the flexible packaging composite film, coated paper and other heat sealing composite membrane. It can also work with tensile tester to do heat seal strength test.

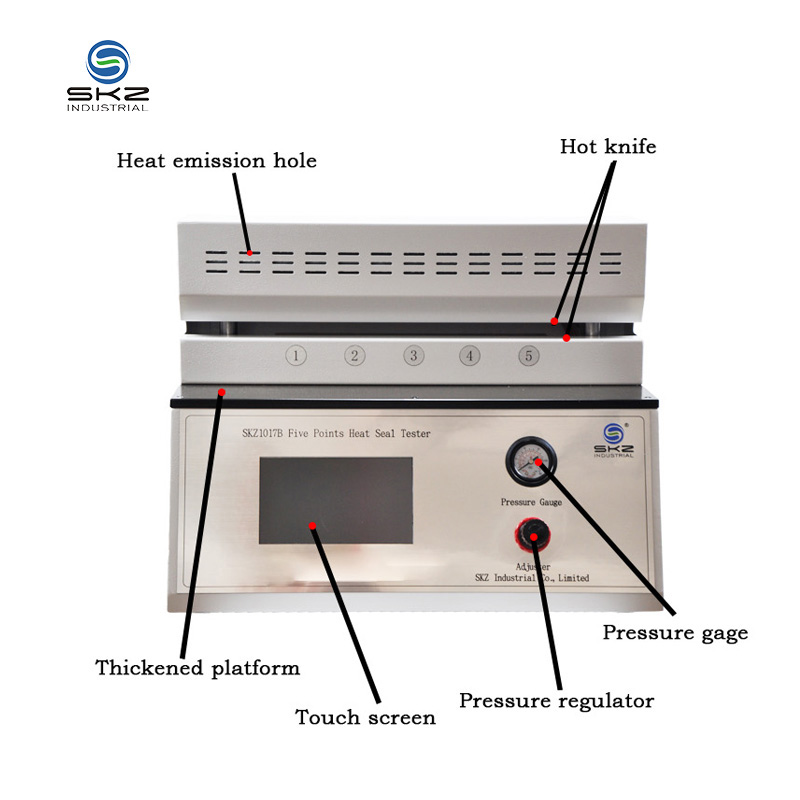

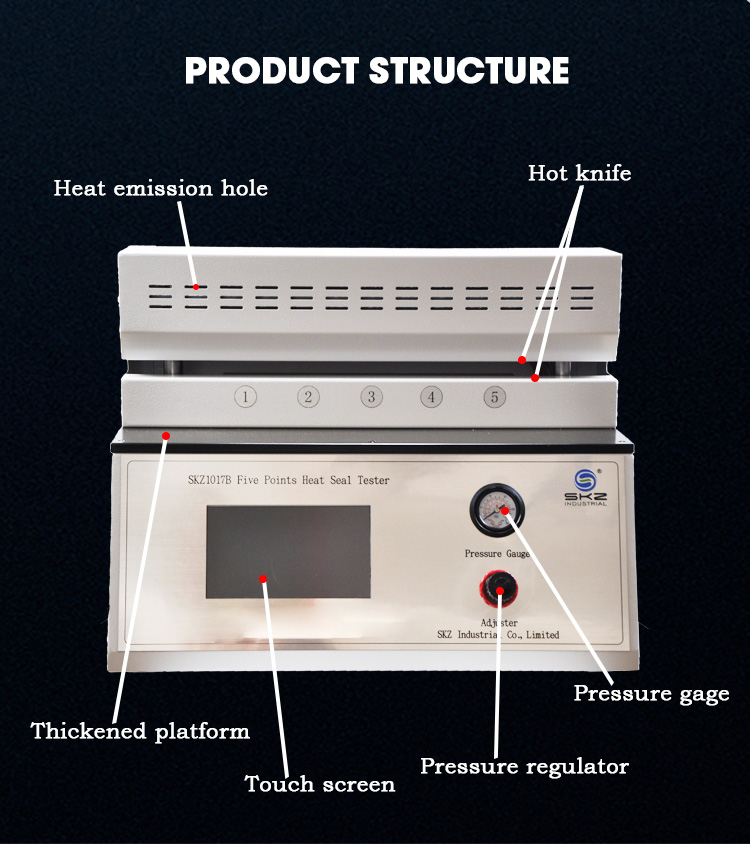

SKZ1017B Five points Heat Seal TesterStructure:

Divided into 4 components of the air power system, warmness sealing device, temperature manage system, time-conditioning systems.

1. Structure:

It contains air drive system, sealing devices, temperature-conditioning systems, time-conditioning systems

2. Air-driven system:

Including pressure gauges, guide rods, cylinder, pneumatic valve, pressure regulator handles, so on. pull out the pressure regulator handle, turn right to increase the sealing pressure, a left turn can reduce the sealing pressure, after finishing the pressure setting and turn the handle to the host side to lockup the air pressure.

3. Sealing device

Composed by the upper and lower sealing bars, upper rods connect with cylinder, and on the upper sealing bar has insulation panels, to prevent transmission of heat to the cylinder. Aluminum rod for sealing, heat sealing the central rod for the heater, above the heat sealing of the lower rod has silica gel plate, can ease the pressure at the time of the impact of heat sealing, back of heat sealing rods are equipped with body temperature.

4. Temperature Control System

upper temperature controller control the upper sealing bars, lower control the lower sealing bar, by adjusting the dial on the button, can set temperature easily.

5. Time-conditioning systems

Sealing time can be set up by adjusting the dial button with range 0.01s ~ 999.9h, in manual mode, press the foot pedal, sealing rods were pressed down; in automatic mode, the upper and lower sealing rods press time from the calculagraph control automatically, once automatic reset. Timer units typically 0.1 seconds, on the panel of the timer have the time adjustment button, sealing time adjustment can be done.

Technical parameters:

Heat seal area | 180mm * 10mm * 5 groups |

Heat seal temperature | room temperature to 300 ° C |

Temperature accuracy | ± 1 ℃ |

Heat seal tim | 0.01s-99.9h |

Heat seal pressure | 10-150psi |

Compressed air | 8kg/cm2 |

Power | 220V 50/60HZ 37VA |

Dimension | 760 * 400 * 54mm |

Weight | 45kg |

SKZ1017B FIVE POINTS HEAT SEALTESTER

We welcome customers to contact us for future businessrelationships and mutual success!

High qualityproduct

Fast Delivery

SpecializedPerfect after-salesfactoryservice

PRODUCT DISPLAY

SKZINTERNATIONALCO,IIMITED

-Product information -

Five-point heat-seal Tester (also known as gradient heat sealtester) can be used to determine the heat sealingtemperature range ,suitable packaging speed, and heatsealing pressure of the plastic film substrate, the flexiblepackaging composite film, coated paper and other heatsealing composite membrane.lt can also work with tensiletester to do heat seal strength test.

Plastic film

Aluminum foil

Coated paper

SKZ10178 Five Points Heat Seal Tester

Pressure Gauge

SKZ Industrial Co. Limited

RODUCT CUSTOMIZATION

We can also customize the logo according to your requirements

(if you have any requirements, please contact us in fime, we will provideyou with the best solution)

Custom Service

SKZ1017B Five Points Heat Seal Tester

WDUSTT

Custom

Pressure Gauge

logo

AdjusterSKZ Industrial Co, Limited

Points Heat Seal fester

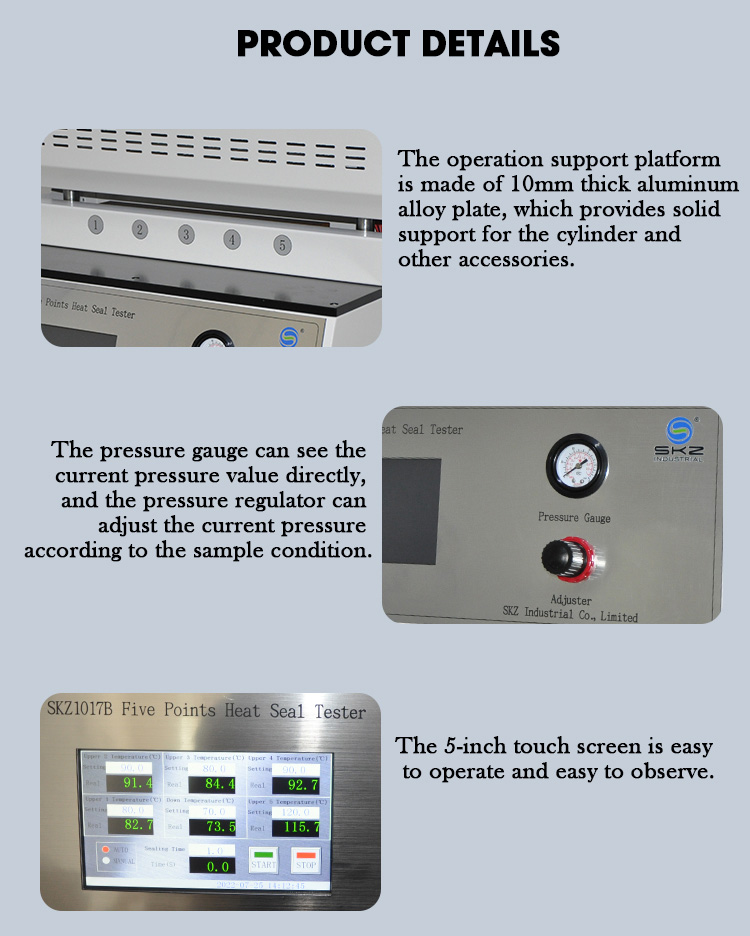

PRODUCT DETAILS

Ihe operation support platformis made of 10mm thick aluminumalloy plate, which provides solidsupport for the cylinder andother accessories.

The pressure gauge can see thecurrent pressure value directlyand the pressure regulator canadjust the current pressureaccording to the sample condition

it Seal Tester

Pressure Gauge

SKZ1017B Five Points Heat Seal Tester

AdjusterSKZ Industrial Co. Limited

The 5-inch touch screen 1s easyto operate and easy to observe

WHY CHOOSE US

SKZ INTERNATIONAL CO., LIMITED

WE HAVE JUST WHAT YOU NEED !

Support customization

Fast delivery

Excellent after-sales service

Reasonable price

SKZ is installed in the 12 months of 2006, we can grant one-stop carrier with professionaland instant pre-sales, mid-sales,and after-sales support.

"SKZ' is the trademark, We surpassed the SÃS/UV inspection certification,CE certificationand lSO certification.

SKZ is Verified Supplier and has obtained19 electricity tags. We have VR showroom andon-site manufacturing facility movies taken. Our merchandise are eligible to take part in exclusivemarketing scenarios, so you can acquire extra reductions from Alibaba.

Searching "SKZ" on www.alibaba.com.

Accept OEM with low MOQ

can at once locate us on top.

Our manufacturing unit covers an vicinity of2500m,We combine design, manufacturing, and serviceto meet the one-of-a-kind necessities of casting, OEM, and processing

We supply a one-year after-sales assurance service. lf repairs or alternative components areneeded, we will negotiate and supply you with the most favorable price.

We have lots inventory for you, fast

delivery

Partners can experience free inn and cateringservices when they come to China

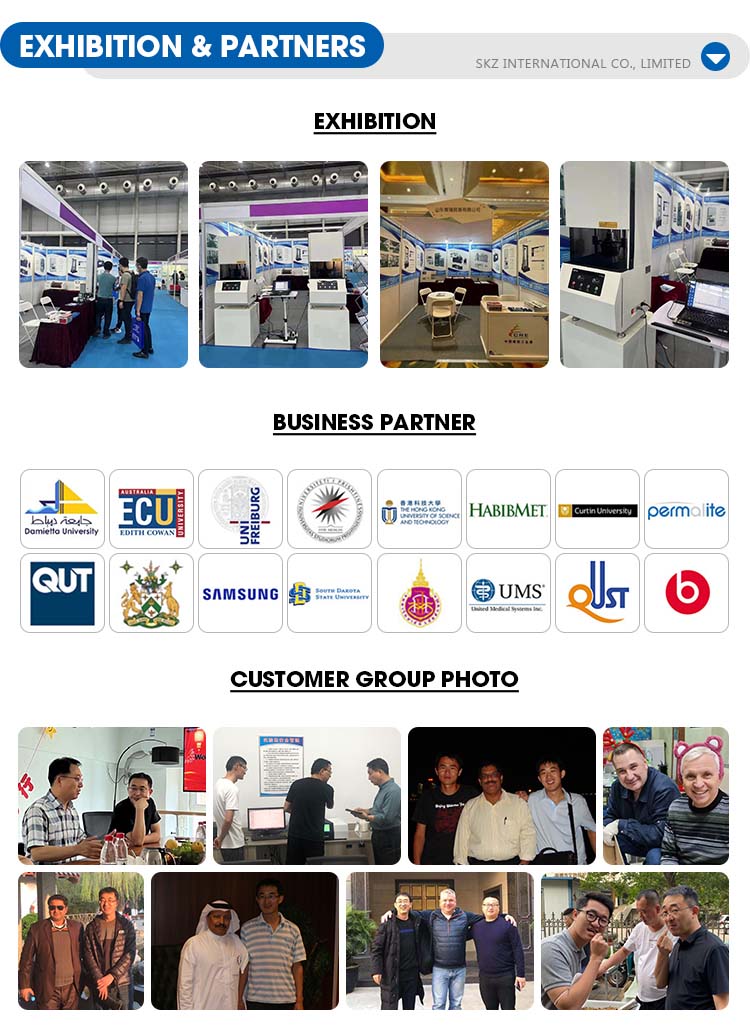

COMPANY PROFILE

SKZ INTERNATIONAL CO.. LIMITED

SKZ Industrial Co. constrained and SKZ International Co LTD are the participants of SKZ group, We are specialised in manufacturing and furnish Lab equipmentScientific instrument, checking out devices for plastic and rubber. "SKZ" is thetrademark, We surpassed the SGS/TUV inspection certification, CE certification andISO certification, SKZ is set up in the yr of 2006, we can grant one-stopservice With expert and immediate pre-sales, mid-sales, and after-sales support.

With extra than sixteen years' ride in the subject of Laboratory Instrumentwe care about your laboratory, greater concemed about your experience, you can locate us 24 hoursseven days a week. Our merchandise have been exported to America, the European Union, SoutheastWe welcome clients to contact us for future commercial enterprise relationships and mutual success!.

PLASTIC RUBBER PROCESS

SKZ INTERNATIONAL CO. LIMITED

MACHINING

We use importedCNClathes for machining,greatlyimproving productionefficiency and shortening shipping time.

PRODUCTION MATERIAL

Each section wants to betested earlier than it can be usedAlso, some key components are imported from aproad.

PRODUCT ASSEMBLY

he people concerned in product meeting are expert employees with over 5 years of workexperience, who cautiously as.semble every phase and confirmthat it is correct.

PRODUCT DEBUGGING

After the manufacturing is completed, we willsimulate the utilization state of affairs and checkwhether the instrument can work properlyfqualified,we will area it in the warehousefor shipment.lfnot qualified, this instru-ment will be rectified till it meets the re.quirements.And we do no longer permit faulty units to be sold. This is our bottomline.

PACKAGING&DELIVERY

We will ship inside 1-2 weeks after confirm-ing the order and receiving payment, however if you have an pressing order,we can additionally take delivery of it.We offer a varety of transportationmethods and courier options. Before ship.ping, we will verify the reliability of the packaging three instances to make sure that thegoods are safely delivered to you