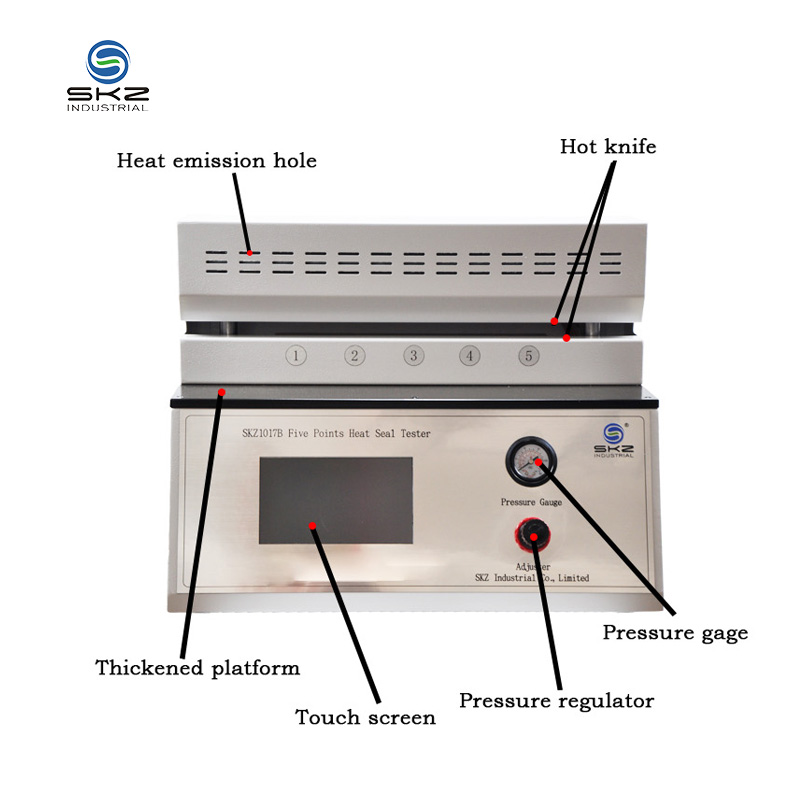

Five points Heat Seal Tester

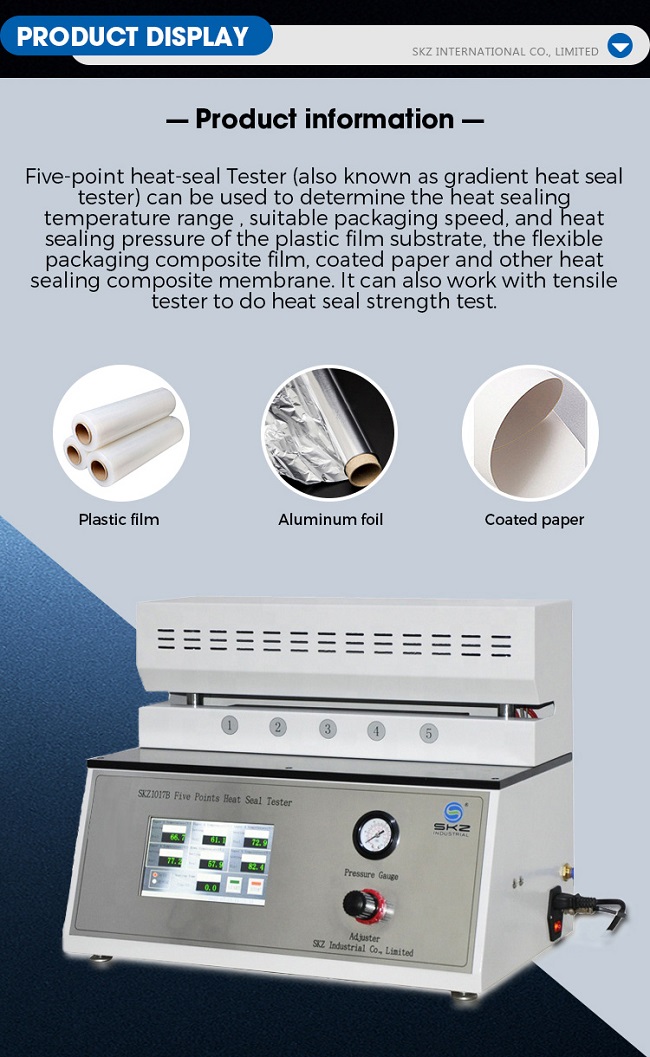

Five-point heat-seal Tester (also known as gradient heat seal tester) can be used to determine the heat sealing temperature range , suitable packaging speed, and heat sealing pressure of the plastic film substrate, the flexible packaging composite film, coated paper and other heat sealing composite membrane. It can also work with tensile tester to do heat seal strength test.

SKZ1017B Five-point heat-seal Tester, to see video click here, to real more product click here, and more follow us on youtube and facebook.

Five-point heat-seal Tester (also known as gradient heat seal tester) can be used to determine the heat sealing temperature range , suitable packaging speed, and heat sealing pressure of the plastic film substrate, the flexible packaging composite film, coated paper and other heat sealing composite membrane. It can also work with tensile tester to do heat seal strength test.

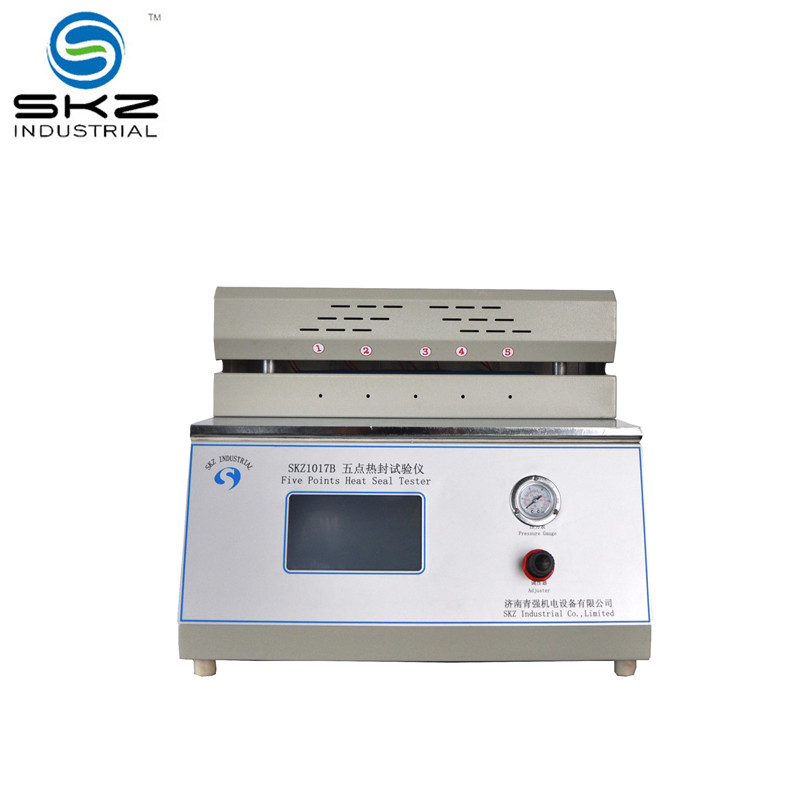

Structure:

Divided into four parts of the air drive system, heat sealing device, temperature control system, time-conditioning systems.

1). Air-driven system

Including pressure gauges, guide rod, cylinder, pneumatic valve, pressure regulator handle.

First pull out the pressure adjustment handle, turn right to increase the sealing pressure, turn left to lower sealing pressure, push the handle towards to the host side after finishing setting the pressure, which can lock the setting values.

2). Heat seal device:

Including the upper and lower heat sealing rods.

Upper heat sealing rods (five segments, each segment control temperature separately), connected with the cylinder, its top has heat shield, to prevent the passing of heat to the cylinder;

lower heat sealing rod’s top has silicone sheet can mitigate the impact of pressure when the heat sealing.

Heat sealing rods is made of aluminum, central part is a heater, the back is equipped with temperature measurement device.

3). Temperature control systems:

Upper and lower five sections of the temperature controller to control the temperature of upper and lower heat sealing rods segment separately, by adjusting the dial buttons can be freely set temperature.

4). Time conditioning system:

By adjusting the dial button, you can arbitrarily set the sealing time, ranging from 0.1 seconds to 99 hours.

Manual mode, control heat-sealing stick to open and close by the foot switch; automatic mode,

Auto mode, controlled by a timer, sealing time can be adjusted by the time adjustment button on the panel, the unit is typically 0.1 seconds.

Technical parameters:

Heat seal area | 180mm * 10mm * 5 groups |

Heat seal temperature | room temperature to 300 ° C |

Temperature accuracy | ± 1 ℃ |

Heat seal tim | 0.01s-99.9h |

Heat seal pressure | 10-150psi |

Compressed air | 8kg/cm2 |

Power | 220V 50/60HZ 37VA |

Dimension | 760 * 400 * 54mm |

Weight | 45kg |