Transient Plane Source Thermal conductivity

1. Our apparatus strictly adheres to the ISO 22007-2 2008 standard 2. The direct measurement approach employed offers a testing window of approximately 5 to 160 seconds, which is adjustable to meet diverse user requirements. 3. One of the key technological advancements of our device is its ability to operate without being influenced by thermal contact resistance. 4. There is no need for elaborate or specialized sample preparation procedures. The device accommodates a wide range of sample shapes, with no specific restrictions. 5. Our testing process is non-destructive, which means that samples can be reused multiple times. This not only reduces the cost associated with sample acquisition and preparation but also aligns with sustainable practices, making it an environmentally friendly and economically viable option. More details click here

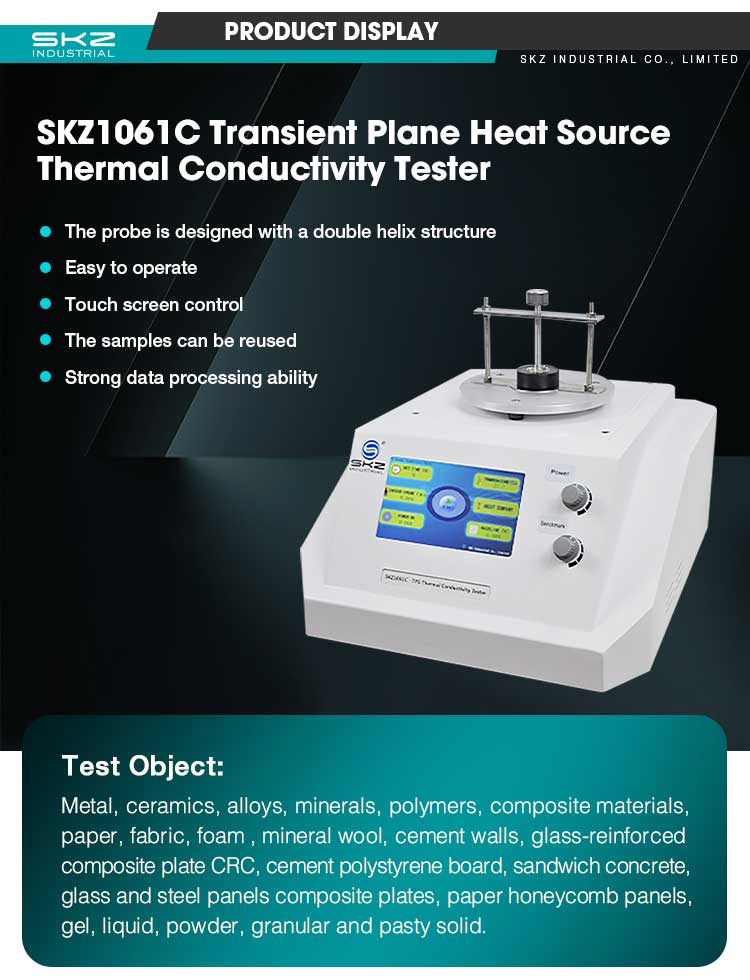

SKZ1061C Thermal Conductivity Testing Equipment** The SKZ1061C Thermal Conductivity Testing Equipment is an outstanding testing instrument that employs the advanced Transient Plane Source (TPS) technique. This new technique, developed by Professor Silas Gustafsson at Chalmers University of Technology in Sweden based on the hot wire method, has elevated the science of thermal conductivity measurement to a new level, providing great convenience for the rapid and accurate measurement of the thermal conductivity of materials in enterprise quality management, material production, and laboratory research.Testing Principle The TPS technique measures thermal properties based on the transient temperature response generated by a disc-shaped heat source in the medium. The thermal resistance material is formed by a flat probe, which serves as both a heat source and a temperature sensor. There is a linear relationship between thermal resistivity, temperature alloys, and resistance. By understanding the change in resistance, heat loss can be determined, thus reflecting the thermal conductivity of the sample. Its probe is made of etched alloy conductive foil with a continuous double helix structure, and the outer double insulating shielding layer is thin, possessing both mechanical strength and electrical insulation. During testing, the probe is placed in the center of the sample. When current passes through, the temperature of the probe rises, and the heat diffuses to both sides of the sample. The diffusion rate depends on the heat transfer characteristics of the material. By recording the temperature response time of the probe, the thermal conductivity is obtained through a mathematical model. Wide Range of Test Objects: It covers metals, ceramics, alloys, minerals, polymers, composite materials, paper, fabrics, foams (smooth surface insulation materials, plates), mineral wool, cement walls, glass-reinforced composite plates CRC, cement polystyrene boards, sandwich concrete, glass fiber reinforced plastic composite plates, paper honeycomb panels, gels, liquids, powders, granules, and pasty substances.

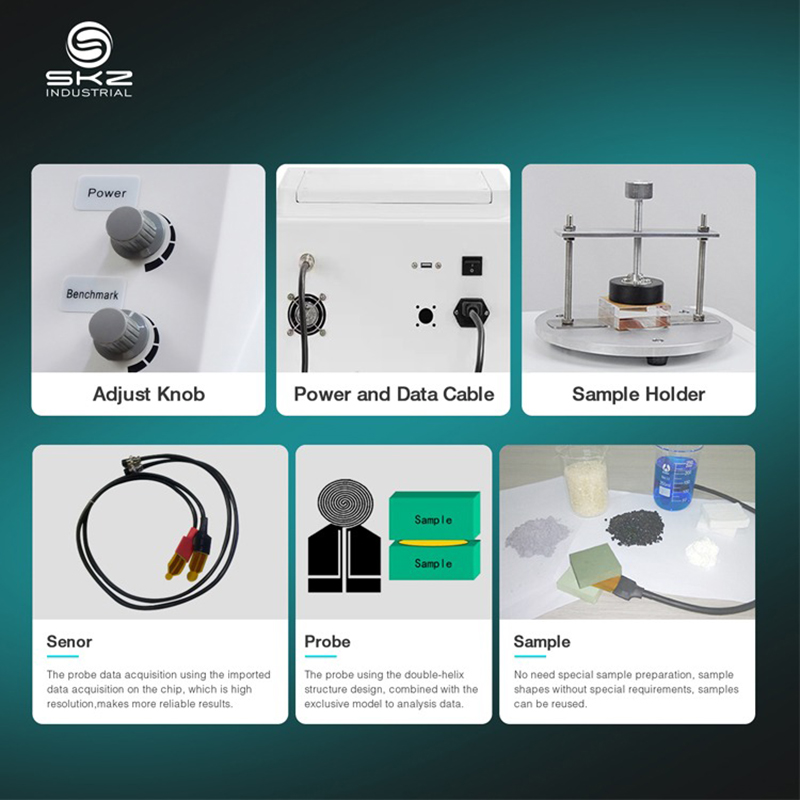

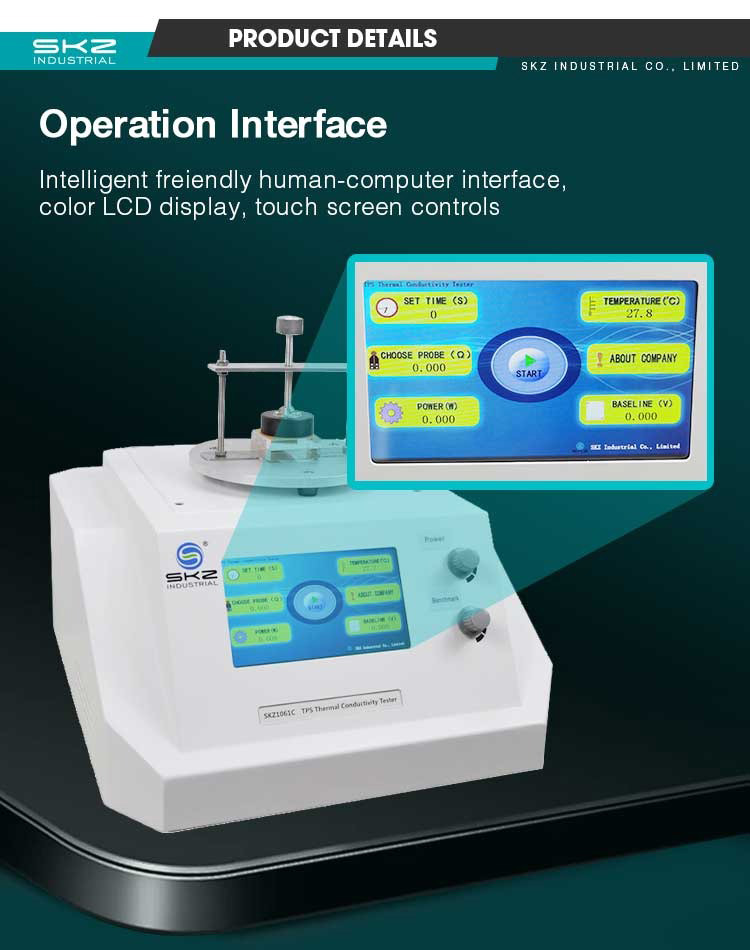

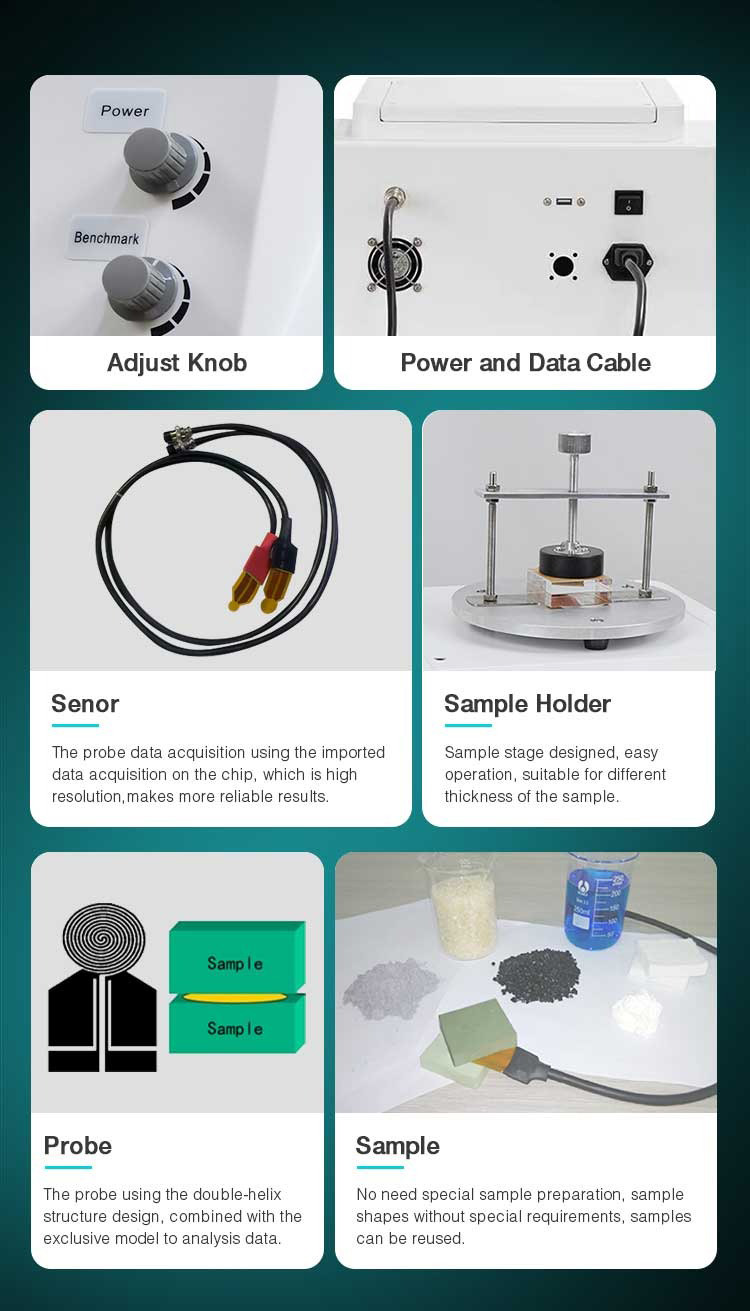

SKZ1061C Thermal Conductivity Testing Equipment 1. This equipment adheres to the ISO 22007-2 2008 standard, ensuring the measurement accuracy and reliability meet international benchmarks. 2. The direct measurement method allows for a testing time ranging from 5 to 160 seconds, which can be customized according to specific needs. This feature enables quick and precise determination of the thermal conductivity coefficient, significantly enhancing testing efficiency and saving valuable time. 3. It is immune to the effects of thermal contact resistance, guaranteeing the purity and accuracy of the measured thermal conductivity values. This eliminates potential errors caused by such resistance, providing more reliable data. 4. There is no need for elaborate sample preparation. The equipment can handle various sample shapes without special restrictions. For bulk solids, a relatively smooth surface and dimensions where the length and width are at least twice the diameter of the probe are sufficient. This simplifies the sample preparation process and broadens the range of applicable samples. 5. The testing process is non-destructive, allowing samples to be reused. This not only reduces the cost of sample acquisition but also aligns with sustainable testing practices. 6. The probe features a double-helix structure design. Combined with a proprietary model, the data collected by the probe is analyzed using a core algorithm. This unique design and analysis method enhance the accuracy and reliability of the measurement results. 7. The sample stage is designed for easy operation and is suitable for samples of different thicknesses. It provides convenience and flexibility during the testing process, accommodating a wide variety of sample sizes. 8. The probe employs imported data acquisition chips with high resolution. This enables more accurate data collection, contributing to more precise and reliable test results. 9. The host control system utilizes an ARM microprocessor, which offers faster processing speed compared to traditional microprocessors. This improvement in processing capacity leads to more accurate measurement results and enhanced overall equipment performance. 10. It can be used to measure various materials, including bulk solids, pasty solids, granular solids, pastes, gels, liquids, powders, coatings, thin films, and thermal insulation materials. This versatility makes it suitable for a diverse range of industries and research fields. 11. The equipment features an intelligent and friendly human-computer interface with a color LCD display and touch screen controls. This interface simplifies operation, allowing users to easily navigate and control the testing process. 12. It possesses powerful data processing capabilities, supported by a highly automated computer processing system for data communication and reporting. This enables efficient management and analysis of test data, facilitating the generation of detailed and accurate reports.

Technical parameters:

Measure method | Transient Plane Heat Source, Unsteady Status |

Measurement physical properties | Direct access the thermal conductivity and thermal diffusivity |

Test object | Solid, liquid, powder, paste, colloid, granule |

Sample size request | No special requested |

Test Range | 0.005--300W/(m*K) |

sample temperature range | Room temperature--130℃ |

Probe diameter | 15mm/7.5mm |

Accuracy | ±3% |

Repeatability | ≤3% |

Measuring time | 5--160 seconds |

Power supply | AC 220V |

Total power | ﹤500w |

Technical parameters:

Measure method | Transient Plane Heat Source, Unsteady Status |

Measurement physical properties | Direct access the thermal conductivity and thermal diffusivity |

Test object | Solid, liquid, powder, paste, colloid, granule |

Sample size request | No special requested |

Test Range | 0.005--300W/(m*K) |

sample temperature range | Room temperature--130℃ |

Probe diameter | 15mm/7.5mm |

Accuracy | ±3% |

Repeatability | ≤3% |

Measuring time | 5--160 seconds |

Power supply | AC 220V |

Total power | ﹤500w |

SKZ1061C Transient Plane Heat Source

It can be used for measuring bulk solids, pasty solid, granular solid, paste.

gel, liquid, powders, coatings, thin film, thermal insulation materials.

The probe is designed with a double helix structure

Easy to operate

Touch screen control

The samples can be reused

Strong data processing ability

The probe data acquisition using the imported data acquisition on the chip, which is high resolution,makes morereliableresults.

No need special sample preparation, sample shapeswithoutspecialrequirements,samples can be reused.

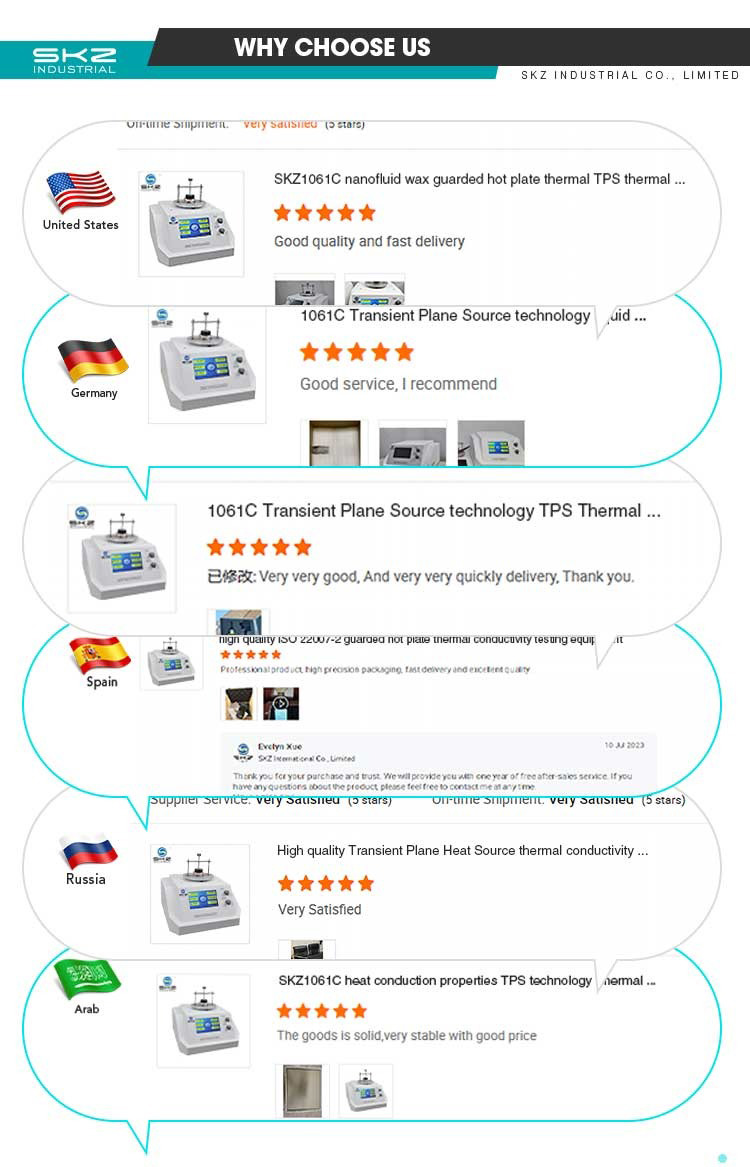

“SKZ" is the trademark, We passed the SGS/TUV inspection certification, CE certification and ISO certification.

We have VR showroom and on-site factory videos taken.SKZ is Verified

Supplier and has obtained 19 strength tags.

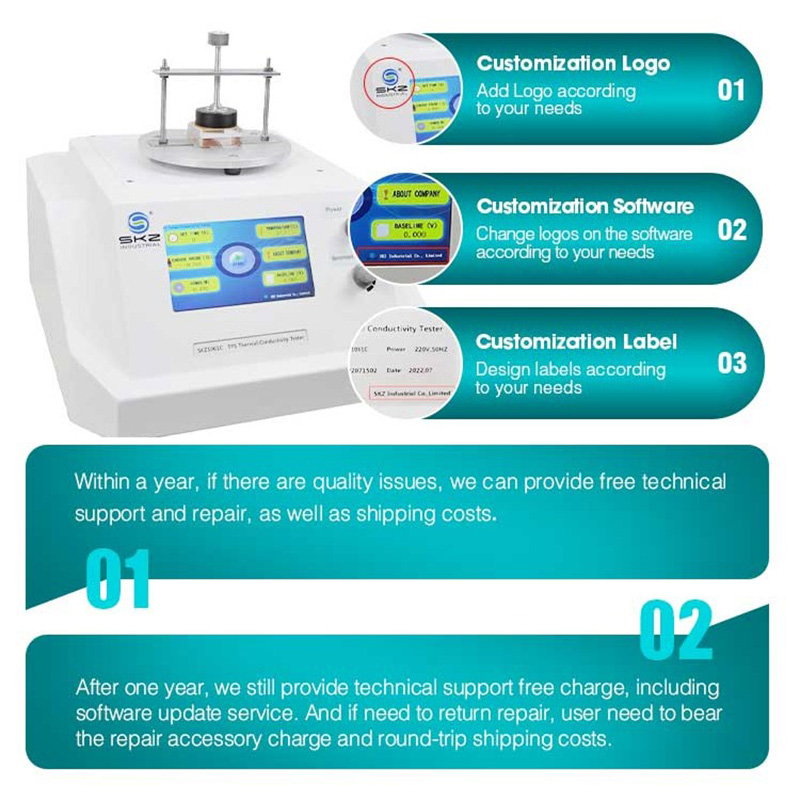

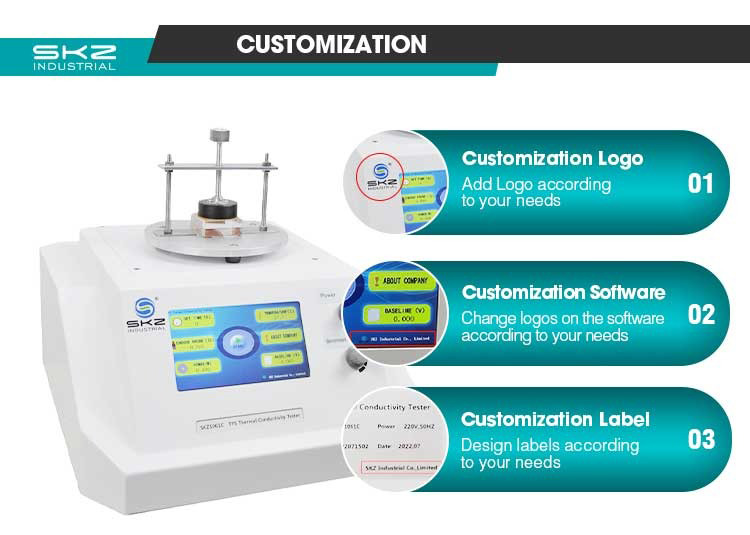

We integrate design, manufacturing, and service to meet the special requirements of casting, OEM, and processing.

Partners can enjoy free hotel and catering services when they come to China

We have plenty stock for you, fast delivery. Accept OEM with low MOQ.

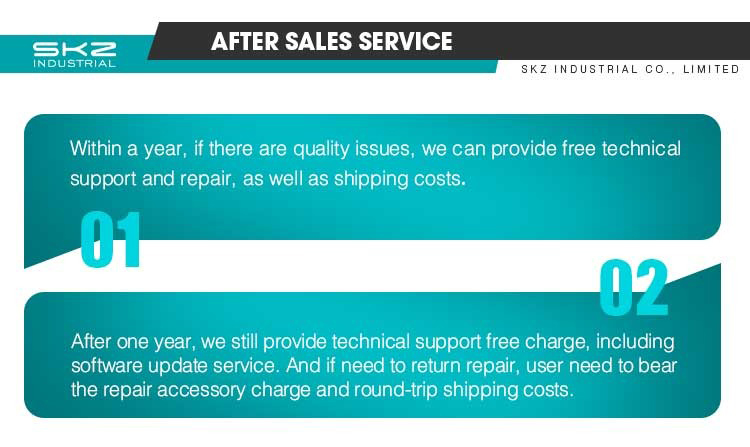

We provide a one-year after-sales warranty service. If repairs or replacement

parts are needed.

SKZ Industrial Co., Limited and SKZ Intemational Co., LTD are the

members of SKZ group, We are specialized in manufacturing and

supply Lab equipment: Scientific instrument, Analytical Instrument.

Thermal Analysis, Moisture meter, Gas detector and testing instru-

ments for pulps, paper, cardboards, plastic, rubber and textile.

'SKZ" is the trademark. We passed the SGS/TUV inspection certifi-

cation, CE certification and ISO certification.

SKZ is established in the year of 2006, we can provide one-stop

service with professional and prompt pre-sales, mid-sales, and

after-sales support.

With more than 16 years' experience in the field of Laboratory

Instrument, we care about your laboratory, more concemed about

your experience, you can find us 24 hours, seven days a week. Our

products have been exported to America, the European Union.

Southeast Asia and Africa.

We welcome customers to contact us for future business relation-

ships and mutual success!