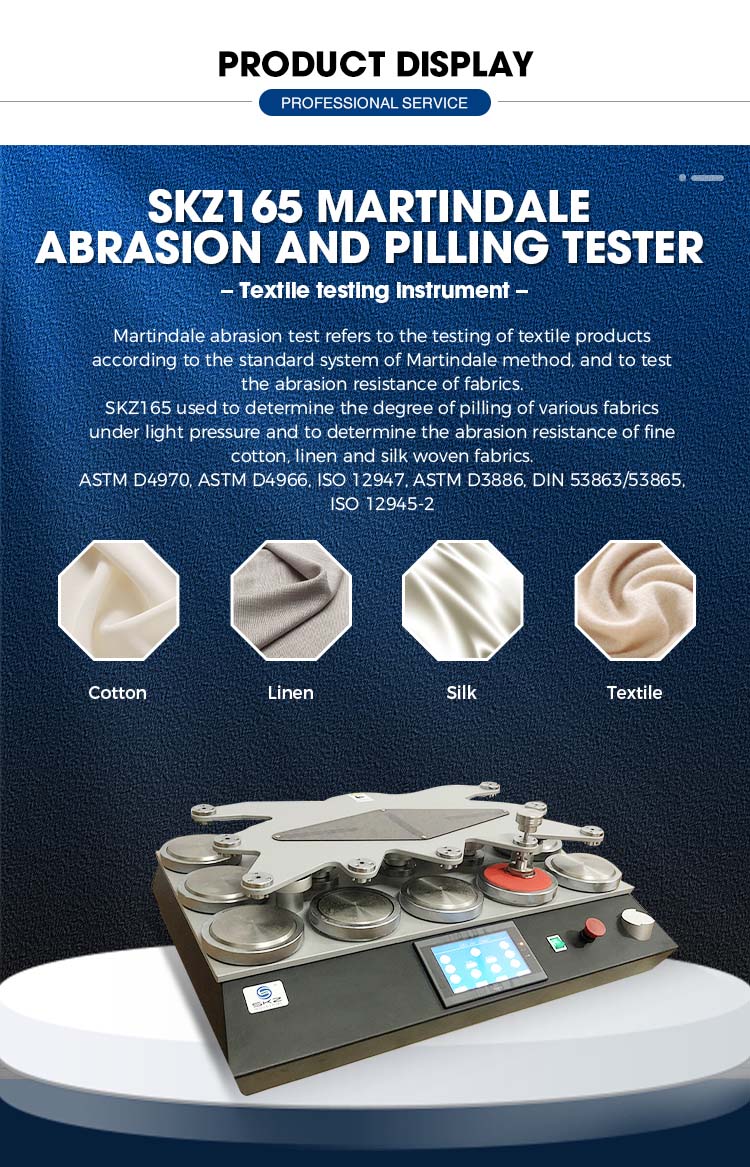

Martindale Pilling Tester

Used to evaluate how well textiles and membrane materials perform in terms of wearing resistance, abrasion, and appearance change (pilling degree/class).

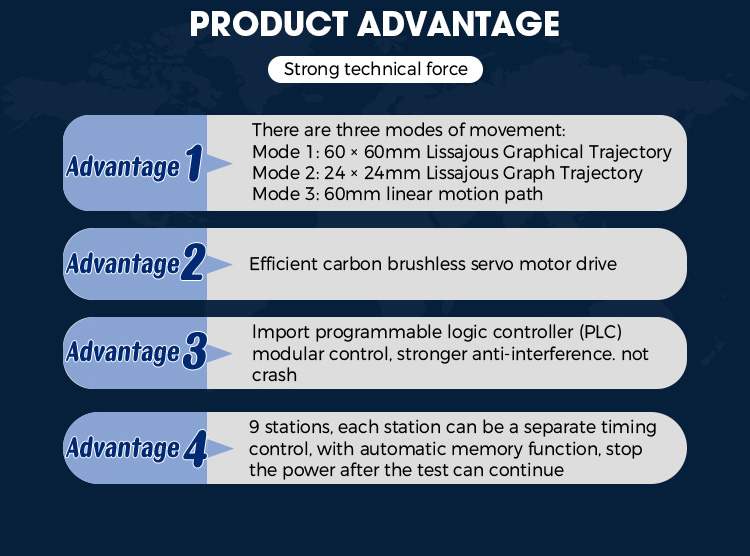

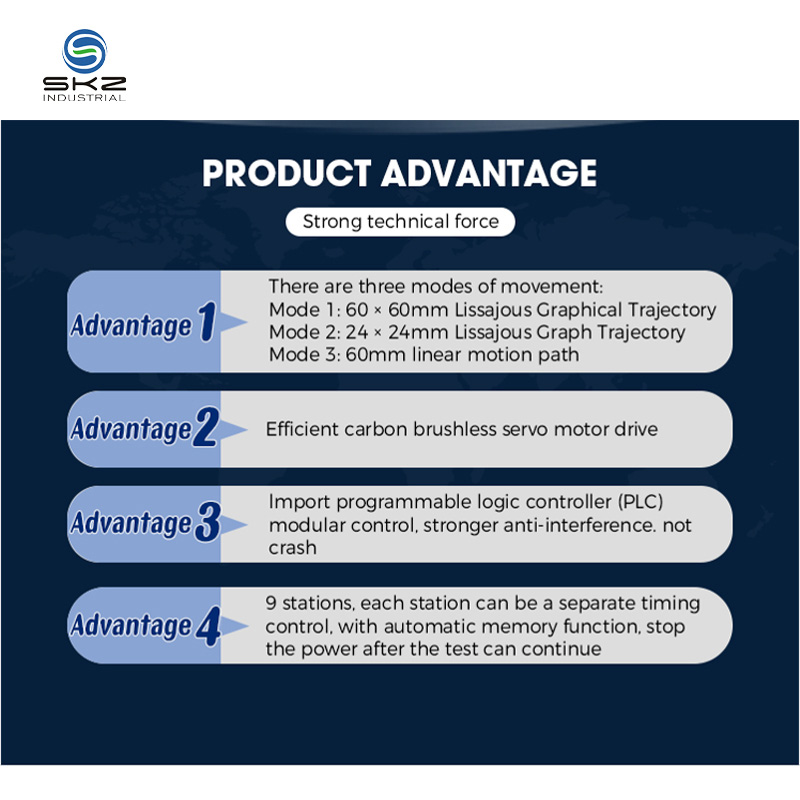

3 ways to move are available:

Mode 1: 60 by 60 mm Graphical Trajectory of Lissajous

Mode 2: Lissajous graph trajectory, 24 x 24 mm

Mode 3: linear motion path of 60 mm

SKZ165A Martindale Pilling Tester Machine real video, click here.

Follow us on Facebook and Youtube. More textile testing equipment,cilck here.

SKZ165 Martindale Pilling Tester

Used to evaluate how well textiles and membrane materials perform in terms of wearing resistance, abrasion, and appearance change (pilling degree/class).

Standards:

ASTM D4970,ASTM D4966,ISO12947,JIS L1096,TM112 M&S, FZ/T20020,IWS TM196,ASTM D3886,DIN53863/53865, BS3424/5690,BS EN 388/530,ISO12945-2

Test mode:

Mode 1: Using a circular specimen made of the same material fabric and friction with a Lissajous graphic motion trajectory, the specimen can reach the necessary speed while assessing sample pilling at a certain pressure. Check to see if the principle and standard agree with the degree of fabric pilling.

Mode 2 involves pressing circular fabric samples and using a conventional abrasive (Lissajous) trajectory curve of mutual friction to cause sample damage. Sample breakage resistance times are used to determine the materials' abrasion resistance. Test for fabric wear resistance based on the idea that it should match the guidelines.

Mode 3: Pressurized, abrasive, and standard fabric samples based on the path line mutual friction, causing sample damage; sample breakage resistance times indicate the materials' abrasion resistance. Test for fabric wear resistance based on the idea that it should match the guidelines.

Features:

1.3 ways to move are available:

Mode 1: 60 by 60 mm Graphical Trajectory of Lissajous

Mode 2: Lissajous graph trajectory, 24 x 24 mm

Mode 3: linear motion path of 60 mm

2. Relative movement speed adjustment mechanism for clamper and mill: 20–70 revolutions per minute.

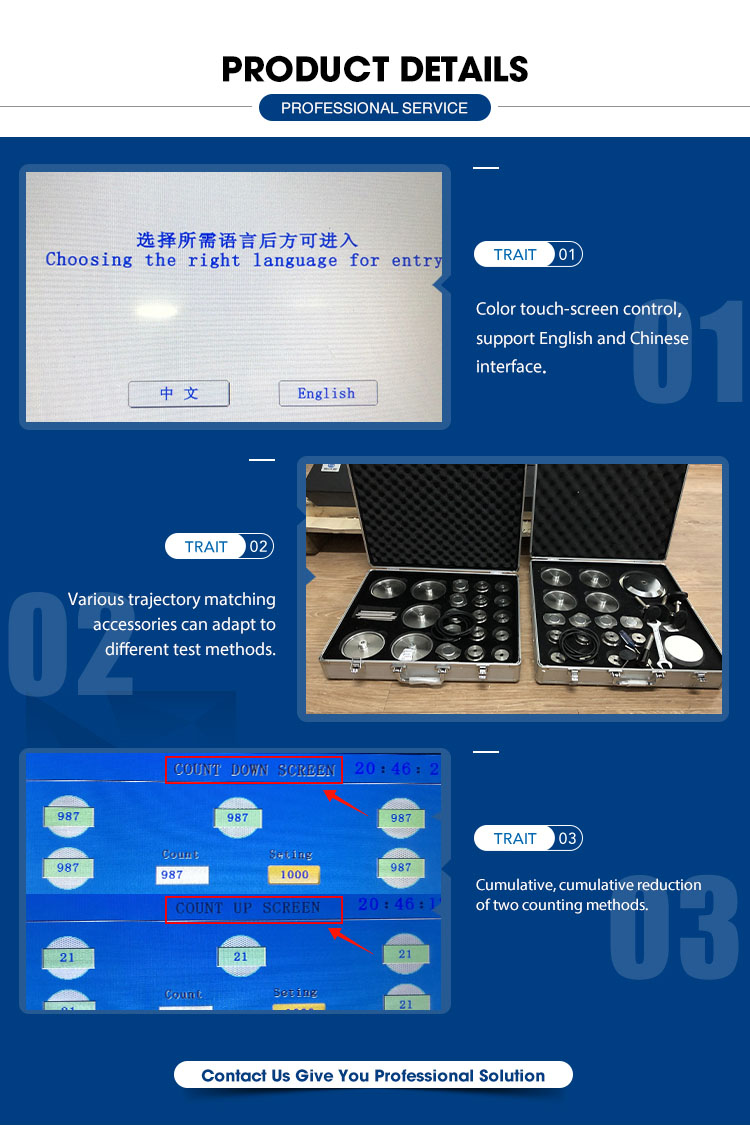

3. A 7-inch, 800 by 480 color touch screen with automated memory function, cumulative configuration, and the ability to reduce two counting ways cumulatively. Each station can serve as an independent time control and can be programmed to shut off the power when the test is finished.

4. Small power and low noise carbon brushless servo motor drive.

5. Import PLCs, which are modular controllers with better anti-interference, do not crash, and may be used for thousands or even hundreds of thousands of long-running.

Technical parameters:

Items | Specification |

Number of working position | 9 |

Counting range | 0~999999 times |

Lissajous graphic motion | 24±0.2mm,60±0.2mm |

Pressures weight | Holder 198g ¢ 28.8 -0.084mm |

fabric sample weight: 395 ± 2g (9KPa) | |

furniture decoration: 594 ± 2g (12KPa) | |

Effective friction diameter | a type 155g friction head ¢ 90 -0.10mm |

b-type 260g friction head ¢ 90 -0.10mm | |

Relative moving speed of clamp and table | 20-70r/min |

Pressing hammer of sample loading | 2385±10g |

Power | Ac220V,50Hz,500W |

Dimension | 885×600×410mm |

Weight | 150kg |