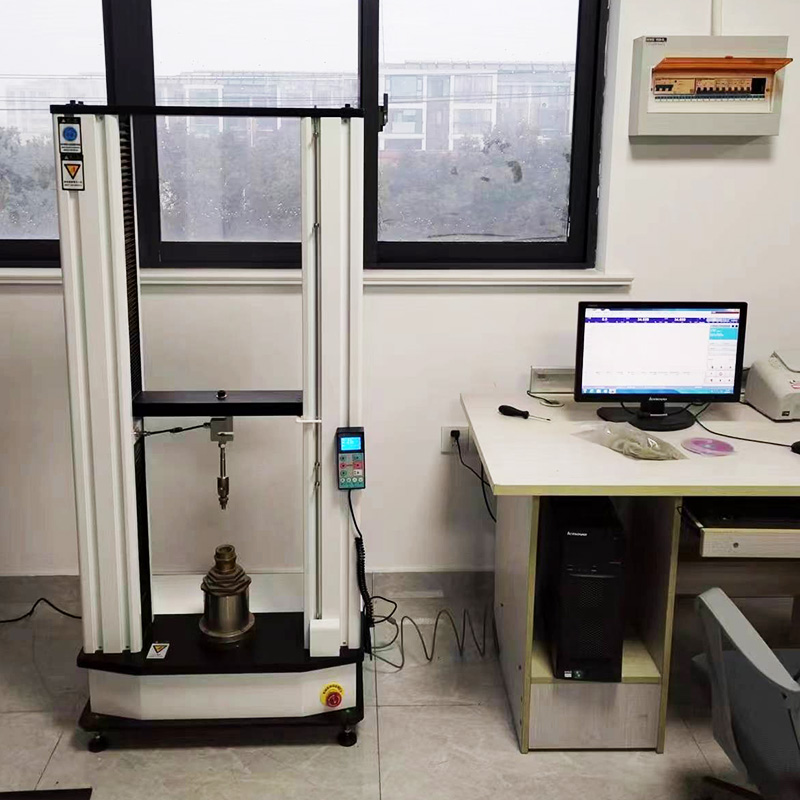

Universal Tensile Testing Machine

For tensile, compression, bending, shear, tear, peel performance test.

Feature

1.Measurement and control software using Windows 7 operating system platform, graphical and graphical software interface, flexible data processing, modular programming language VB, safety limit protection.

2.With automatic algorithm generation, automatic test report editing capabilities

3.Calculate the maximum force, yield strength, non-proportional yield strength, average peel force, elastic modulus

More rubber tester,click here.

SKZ0154 Universal Tensile Testing Machine

For tensile, compression, bending, shear, tear, peel performance test.

Feature

1.Use of the Windows 7 operating system platform, graphical and graphical software interface, flexible data processing, modular programming language (VB), and safety limit protection are features of the measurement and control software.

2. With the ability to automatically create algorithms and change test reports

3. Determine the elastic modulus, average peel force, yield strength, non-proportional yield strength, and maximum force.

Control software introduction

1.Test curve: pressure price - deformation, pressure price - time, stress - strain, stress - time, deformation - time, pressure - time

2.Unit switching: N, kN, lbf, Kgf, g

3.Operating language: English

4.Interface: USB

5.Provide curve processing function

6.Multi-sensor guide feature (optional)

7.The machine affords the customized system of parameter formula, the person can outline the parameter calculation method in accordance to the necessities and edit the file in accordance to the need

8.Test facts the use of database management, robotically shop all take a look at information and curves

9.Test records can output into EXCEL form

10. Multiple check facts and curves for the identical set assessments can be printed in single report

11. Historical information can be brought collectively for comparative analysis

12. Can be robotically calibrated: calibration process, enter the general price in the menu, the device can routinely calibrate the indication cost

Technical Parameters

Maximum force | 0-5kN |

Force accuracy | ± 1.0% |

Force resolution | 1/250000 |

Effective stretching stroke (excluding fixtures) | 900mm |

Accuracy: ± 1.0% | |

Resolution: 0.001mm | |

Effective test width | 360mm |

Deformation | Accuracy Indication within ± 0.5% |

Resolution: 0.005mm | |

Speed | 0.01mm / min ~ 500mm / min (ball screw + servo system) |

Print function | Print out the maximum force, tensile strength, elongation at break and corresponding curve |

Power | AC220V ± 5% 50Hz or 60HZ |

Dimension | 690mm × 570mm × 1600mm |

Weight | 180kg |

Packing list

Items | Quantity |

Sensor | 1PC |

Precision ball screw | 1PC |

High-precision reducer | 1PC |

Brand optical encoder | 1PC |

Standard tensile fixture | 1PC |

control est software (including tensile, compression, shear, bending, tearing, peeling). | 1PC |