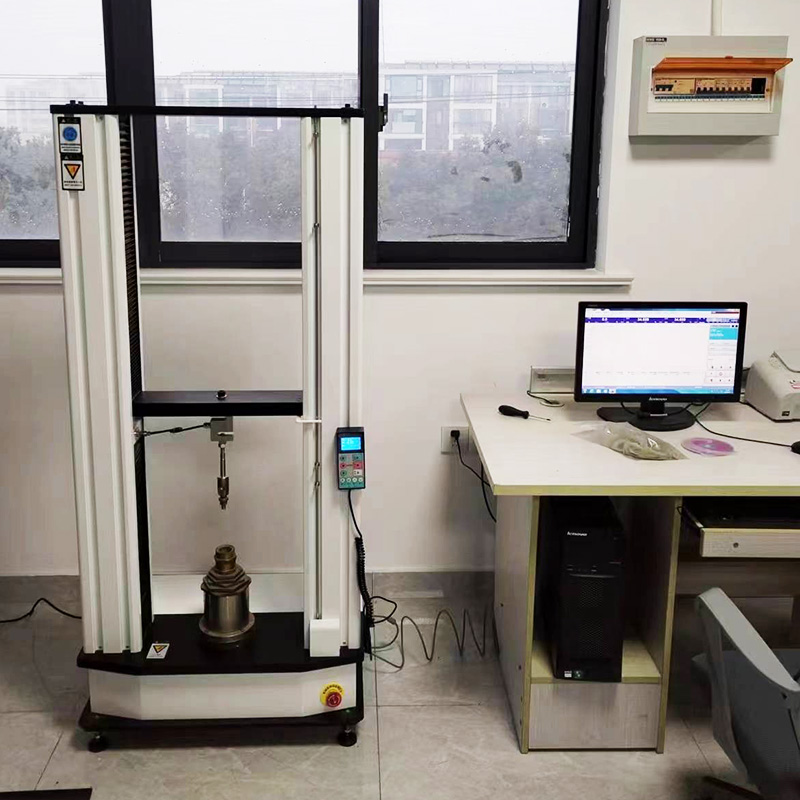

Universal Tensile Machine

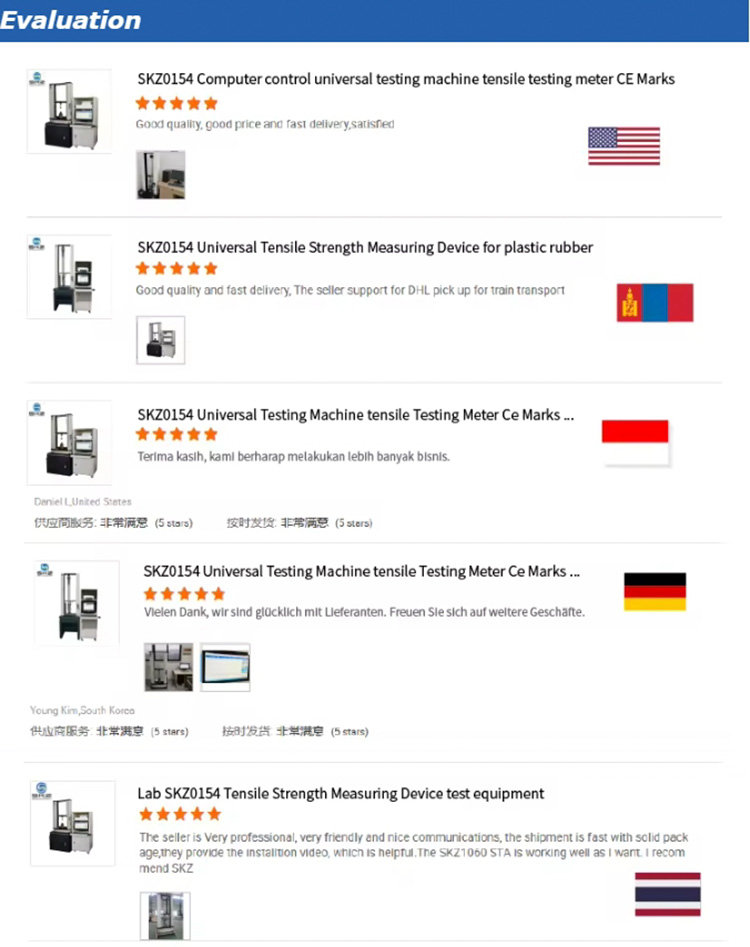

Performance tests include tensile, compression, bending, shear, tear, and peel.

Feature

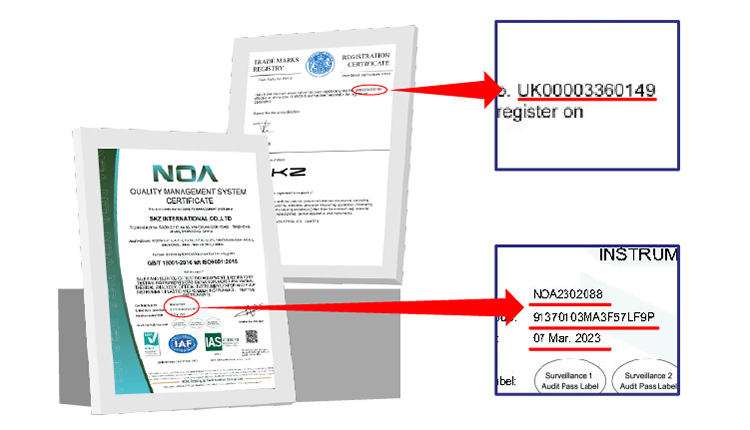

1.Using the Windows 7 operating system platform, measurement and control software has a graphical user interface, flexible data processing, modular programming in VB, and safety limit protection.

2.Equipped with automated algorithm development and automated test report editing features.

3.Determine the elastic modulus, average peel force, maximum force, yield strength, and non-proportional yield strength.

More rubber testing machine,click here.

SKZ0154 Universal Tensile Machine

Performance tests include tensile, compression, bending, shear, tear, and peel.

Feature

1.Using the Windows 7 operating system platform, measurement and control software has a graphical user interface, flexible data processing, modular programming in VB, and safety limit protection.

2. Equipped with automated algorithm development and automated test report editing features.

3. Determine the elastic modulus, average peel force, maximum force, yield strength, and non-proportional yield strength.

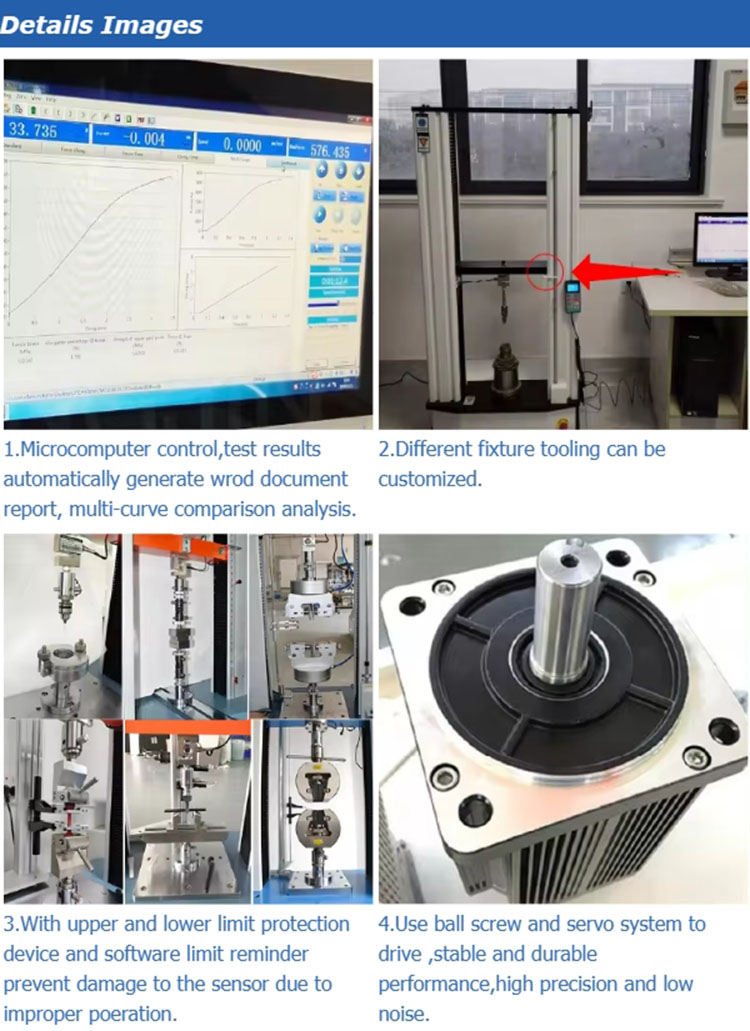

introduction of control software

1. The test curve displays the following data: force value, deformation, duration, stress, strain, deformation, and strain.

2. Swapping units: N, kN, lbf, Kgf, g

3. English is the operating language

4. USB interface

5. Offer a function for processing curves.

6. Support for multiple sensors (optional) 7. The system offers a custom parameter formula; the user can provide the formula for calculating parameters based on requirements and modify the report as necessary.

8. Test data is managed via a database, and all test data and curves are automatically saved.

9. Test results can be exported to Excel

10. A single report can publish several test data and curves for the same set of tests.

11. Historical information can be combined for analysis through comparison.

12. The system is capable of automatically calibrating the indication value. To do this, simply input the standard value in the menu and follow the calibration process.

Technical Parameters

Maximum force | 0-5kN |

Force accuracy | ± 1.0% |

Force resolution | 1/250000 |

Effective stretching stroke (excluding fixtures) | 900mm |

Accuracy: ± 1.0% | |

Resolution: 0.001mm | |

Effective test width | 360mm |

Deformation | Accuracy Indication within ± 0.5% |

Resolution: 0.005mm | |

Speed | 0.01mm / min ~ 500mm / min (ball screw + servo system) |

Print function | Print out the maximum force, tensile strength, elongation at break and corresponding curve |

Power | AC220V ± 5% 50Hz or 60HZ |

Dimension | 690mm × 570mm × 1600mm |

Weight | 180kg |

Packing list

Items | Quantity |

Sensor | 1PC |

Precision ball screw | 1PC |

High-precision reducer | 1PC |

Brand optical encoder | 1PC |

Standard tensile fixture | 1PC |

control est software (including tensile, compression, shear, bending, tearing, peeling). | 1PC |