Rapid-kothen Sheet Former

Standards: ISO5269/2

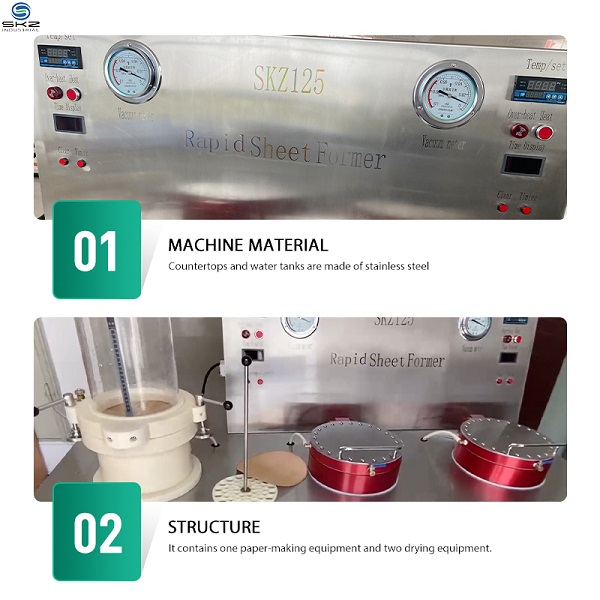

Part two: the fast sheet former method. It contains one paper-making equipment and two drying equipment.

Kindly check the video of SKZ125 Rapid-kothen Sheet Former

Please click here to learn more about the paper and paperboard testing

Follow us on Youtube and Facebook

Feature:

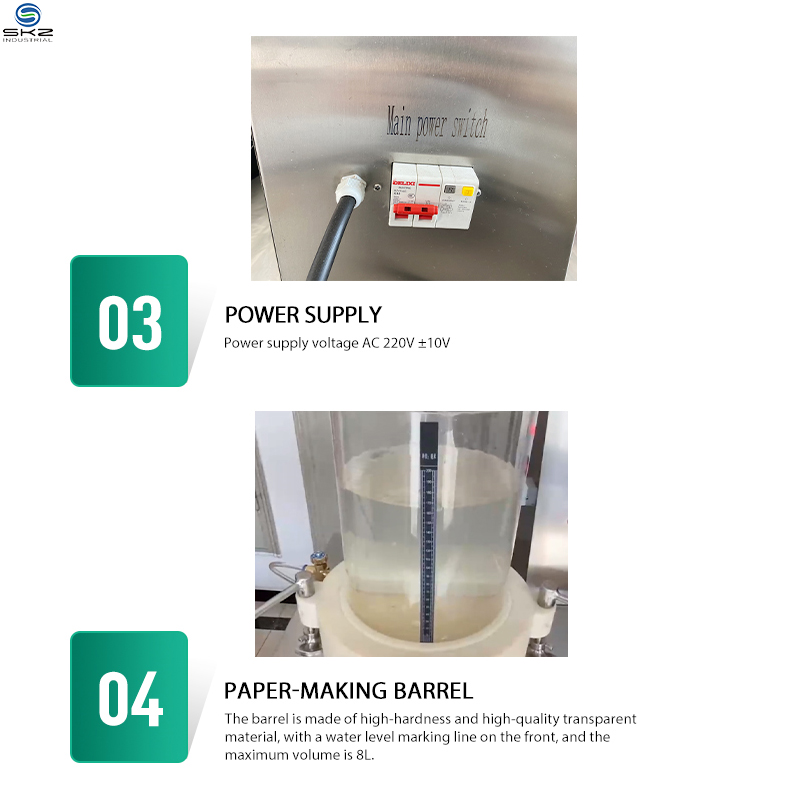

1.Mainly composed by dryers, vacuum pumps, and sheet former (press)

2.Sheet former parts: power-driven drain off water, white water cycle use, power-driven feed water,

aerodynamic homogenate ( also can manual homogenate), Water molding or vacuum pump suction molding

3.Dry parts adopt vacuum heating and drying, vacuum pump adopts water cycle, heating element use heating plate,

temperature control system, and has a short circuit, disconnection, and automatic over-temperature alarm function, with a stop anti-oil return.

4.Countertops and water tanks are made of stainless steel

Technical data:

Sample Dia | ≦200mm |

Dry Dia | Φ200mm |

Height of vacuum pump | -0.06~-0.09MPa |

Sucking rate of vacuum pump | 60CBM/H. (water cycle) |

Drying Temp | 95℃-120℃ |

Drying time | (GSM 30-85g/㎡): 3~5Minutes |

Compressor | 2P |

Heating power | 1.5KW×2 |

Dimension | 1700mm×700mm×1200mm |

Weight | 300KG |