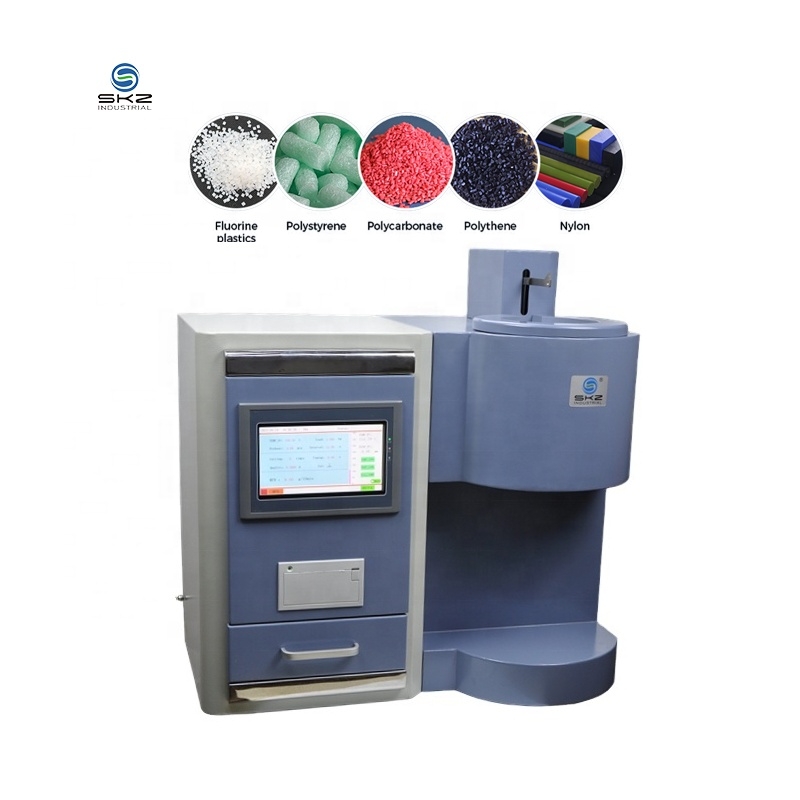

Melt Flow Rate Tester

Melt mass-flow (MFR) (g/10min), melt volume-flow rate (cm3/10min), and the melt density of thermo resin must be determined for engineering plastics, which have higher melt temperatures, such as polycarbonate, nylon, and fluorine plastics; and for fit for plastics tests, which have lower melt temperatures, such as polyethylene, polystyrene, polypropylene, ABS resin, and poly-formaldehyde resin, etc.

Standards:

ISO 1133-1, ISO 1133-2, GBT 3682.1-2018, ASTM D1238-2013, ASTM D3364-1999 (2011), JJG878-1994, JB/T5456-2016, DIN53735, UNI-5640

SKZ145 melt flow rate tester video,click here.

More hot sale products,click here.

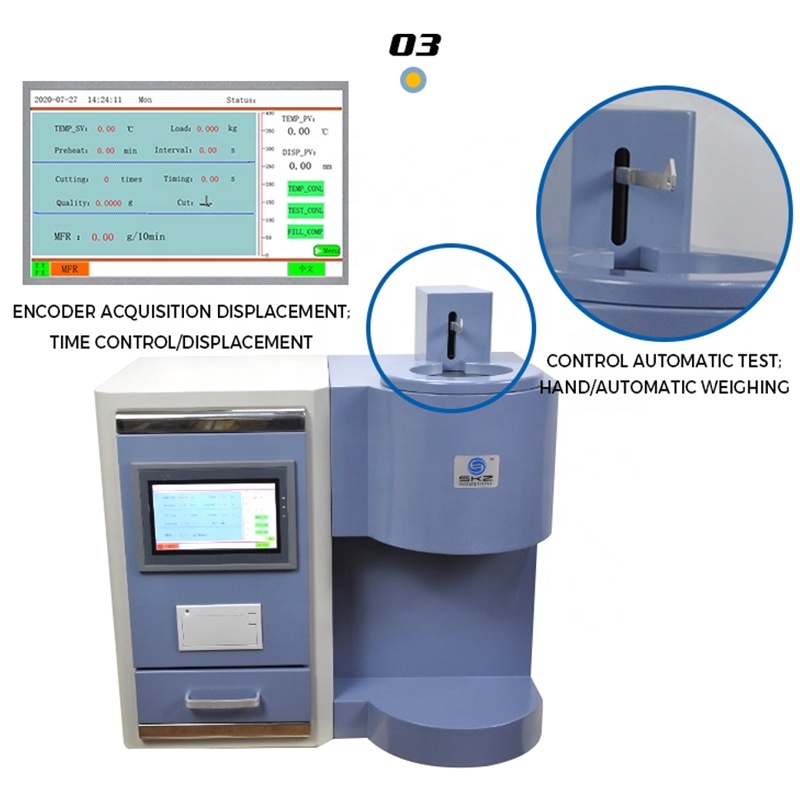

SKZ145 Melt Flow Rate Tester

Melt mass-flow (MFR) (g/10min), melt volume-flow rate (cm3/10min), and the melt density of thermo resin must be determined for engineering plastics, which have higher melt temperatures, such as polycarbonate, nylon, and fluorine plastics; and for fit for plastics tests, which have lower melt temperatures, such as polyethylene, polystyrene, polypropylene, ABS resin, and poly-formaldehyde resin, etc.

Standards:

ISO 1133-1, ISO 1133-2, GBT 3682.1-2018, ASTM D1238-2013, ASTM D3364-1999 (2011), JJG878-1994, JB/T5456-2016, DIN53735, UNI-5640

Product features:

1.The control system and heating furnace are assembled separately from the main machine, which protects the control system from damage caused by high temperatures, which limit component life. It is clean and elegant, spray-painted, and simple to assemble and disassemble.

2.The piston rod and barrel are made of alloy materials with a low expansion coefficient and good temperature resistance. To ensure data accuracy, the surface is heat treated to make it non-deformable, extremely hard at high temperatures, and impossible to wear over time.

3.The displacement is detected with a rotary encoder, and measurement errors are effectively eliminated since the lever principle is employed to ensure that the front and rear balance without the need for additional components such as springs.

4.A cutting device having a micromotor-controlled mechanism that enables for manual or timed operation. The technique is simple to follow. The cutting knife was made of high-strength spring steel to prevent deformation or equipment damage after continuous operation.

5.It features a 7-inch touchscreen display. The interface can rapidly and exactly detect the current test state, and it is simple to use, intuitive, and information-rich.

7.This equipment can save five sets of test data, has no test type limitations, may be stored permanently, and will not be erased after a power loss.

8.Users can easily update because the control board has various signal ports dedicated for them.

9.During the test, the user will receive numerous warnings to remind them of the device's current state, which will be displayed on the touchscreen.

10.Humanized design: The system settings include touch sound and lighting customization to match the user's operation habits.

11. Assist users: Provide a list of common failure circumstances and solutions.

12. You can switch between Chinese and English at any time.

13. Each exam results report is available in both Chinese and English.

14. When the temperature control system closes, it will prompt the user to confirm that the cleaning is complete, considerably reducing the likelihood that the equipment will be harmed if the user forgets to clean the material.

Specification

Measure range | 0. 01-600.00 g/10min (MFR) |

0. 01-600.00 cm3/10min(MVR) | |

Temperature range | 0-400℃ |

Temperature Fluctuation | ±0.2℃ |

Temperature gradient | ≤0.5°C (within 10~70mm of the upper end of the die in the barrel) |

Temperature resolution | 0.01℃ |

Measuring method | MFR MVR |

Material canister | Inner diameter : 9.55±0.007mm |

Inner length :160mm | |

Mould | Inner diameter: 2.095mm |

length: 8±0.025mm | |

Barrel temperature recovery time after feeding | ≤4min |

Displacement measure range | 0-30mm |

Displacement accuracy | ±0.02mm |

Displacement resolution | 0.01mm |

Timing accuracy | 0.01s |

Load | full load |

Base weight | (piston weight + base poise weight) 0.325Kg |

Weights (poise) | 0.875Kg, 1.290Kg, 1.835Kg, 3.475Kg, 4.675Kg, 5.000Kg, 5.000Kg one each (may freewill combination ) |

Poise can be | 0.325Kg,1.0Kg,1.2Kg,2.16Kg,3.8Kg,5.0Kg,10.0 Kg,21.6Kg |

Poise Accuracy | ≤±0.5% |

Supply Power | AC220V±10% 50Hz |

Heat up power | 550W |

Dimension | 580×480×530 |

Weight | 110kg |