Heating Temperature Aging Oven Chamber

Used to carry the heat-ageing test for plasticity material, insulation material.

Temperature controlled by digital display, PID auto adjustment, can arbitrarily set the working temperature from room temperature to 200℃ or 300℃, automatically keep temperature,

to real more product click here.

WhatsApp/Cell: +8618678395869

Skype: +8618678395869

Wechat: +8618678395869

Heating Temperature Aging Oven Chamber

Stainless steel tank and digital display, its working temperature can reach to the highest point from room temperature, which can also be adjusted arbitrarily.

We have over 15 years experience in the field, centralized procurement available, We care about your lab, more concerned about your experience.

Our products have been exported to Southeast Asia, Australia, Africa, America, the European Union and the Middle East .

Standard:

ISO 188-- Rubber, vulcanized or thermoplastic--Accelerated ageing and heat resistance tests--Air-oven method.

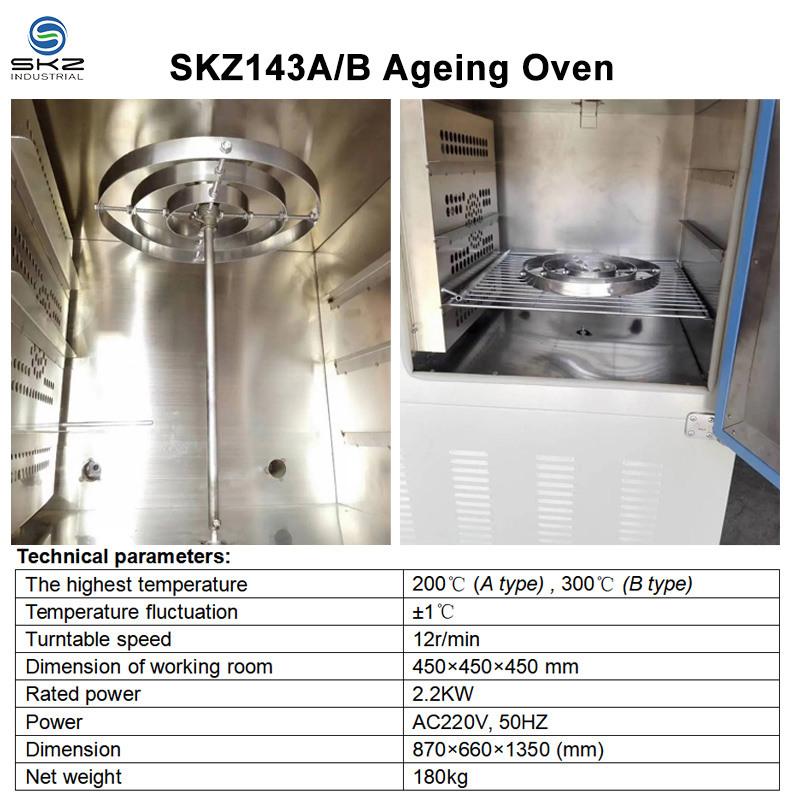

Technical parameters:

The highest temperature | 200℃ (A type) , 300℃ (B type) |

Temperature fluctuation | ±1℃ |

Turntable speed | 12r/min |

Dimension of working room | 450×450×450 mm |

Rated power | 2.2KW |

Power | AC220V, 50HZ |

Dimension | 870×660×1350 (mm) |

Net weight | 180kg |

TEMPERATURE CONTROLLED BYDIGITAL DISPLAY

POWVEF

WORKING TEMPERATURE:

FROM ROOM TEMPERATURE TO200℃ (A TYPE) OR 300'℃ (B TYPE)

DIMENSION OF WORKING ROOM:450x450x450 MM

PID AUTO ADJUSTMENT

AUTOMATICALLY KEEPTEMPERATURE.

SKZ INTERNATIONAL CO.. LIMITED

SKZ Industrial Co., Ltd. and SKZ International Co., Ltd. are esteemed members of the SKZ Group, which is dedicated to the production and distribution of laboratory equipment, scientific instruments, and testing devices for the plastics and rubber industries. The "SKZ" brand is our registered trademark, and we have successfully obtained certifications from SGS/TUV, CE, and ISO, reflecting our commitment to quality. Since our inception in 2006, SKZ has been offering comprehensive services, backed by expert and efficient pre-sales, sales, and post-sales support.

With over 16 years of expertise in laboratory instrumentation, we are deeply committed to enhancing your laboratory experience. You can reach us around the clock, every day of the week. Our products have been shipped to various markets, including the United States, the European Union, and Southeast Asia. We extend a warm invitation to potential customers to engage with us for establishing long-term business partnerships aimed at mutual growth and success.

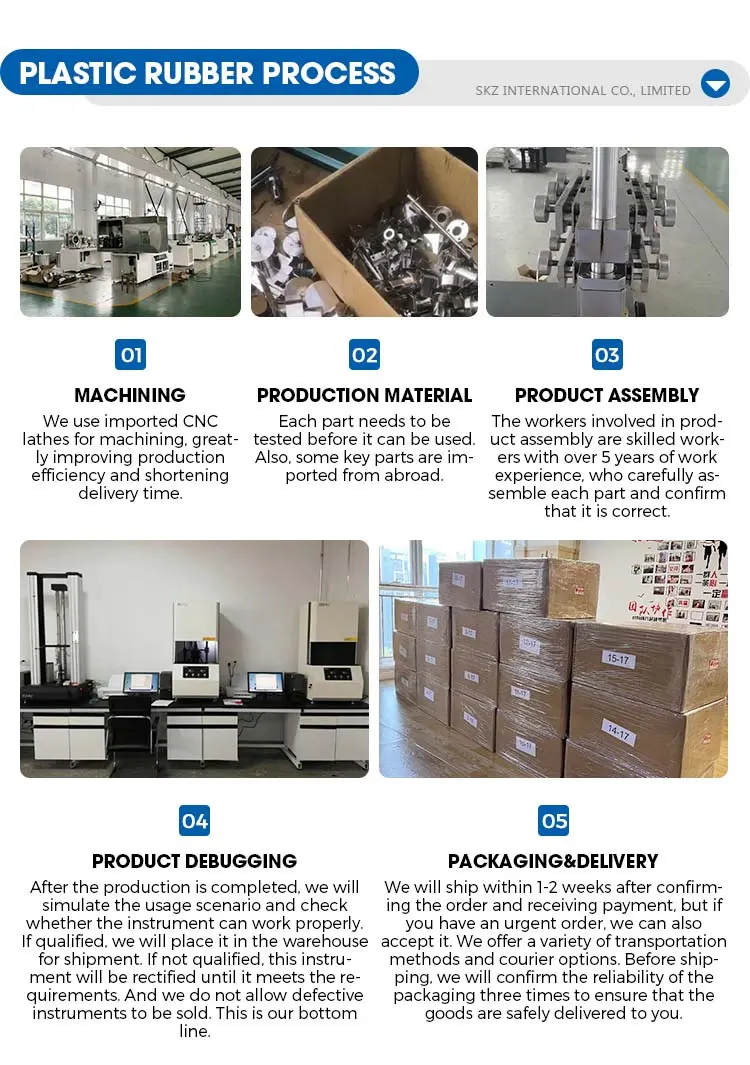

PLASTIC RUBBER PROCESS

SKZ INTERNATIONAL CO. LIMITED

MACHINING

We use importedCNClathes for machining,greatlyimproving productionefficiency and shortening delivery time.

PRODUCTION MATERIAL

Each part needs to betested before it can be usedAlso, some key parts are imported from aproad.

PRODUCT ASSEMBLY

he workers involved in product assembly are skilled workers with over 5 years of workexperience, who carefully as.semble each part and confirmthat it is correct.

PACKAGING&DELIVERY

We will ship within 1-2 weeks after confirm-ing the order and receiving payment, but if you have an urgent order,we can also accept it.We offer a varety of transportationmethods and courier options. Before ship.ping, we will confirm the reliability of the packaging three times to ensure that thegoods are safely delivered to you.