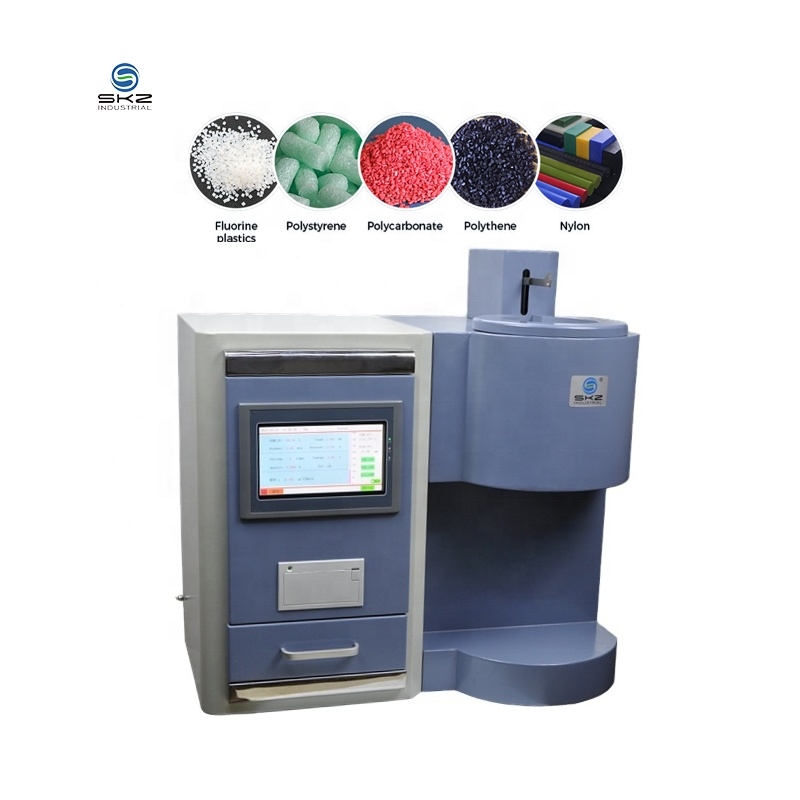

Auto LCD MFR Machine

To determine the melt mass-flow MFR (g/10min), the melt volume-flow rate MFV(cm3/10min) and the melt density of thermo resin, for the engineering plastics of polycarbonate, nylon and fluorine plastics, whose melt temperature are higher, but also fit for the plastics tests of polyethylene, polystyrene, polypropylene, ABS resin and poly-formaldehyde resin, etc, whose melt temperature are lower, widely applied to the fields of plastics materials, product, petrochemical.

SKZ145 LCD Melt Flow Indexer, to real more product click here, and more follow us on youtube and facebook.

SKZ145 ISO1133 Manufacture Auto LCD Melt Flow Indexer Factory Melt Flow Indexer

Standards:

ISO 1133-1:2011 Plastics — Determination of the soften mass-flow price (MFR) and soften volume-flow price (MVR) of thermoplastics —Part 1:Standard method

ISO 1133-2:2011 Plastics — Determination of the soften mass-flow charge (MFR) and soften volume-flow charge (MVR) of thermoplastics —Part 2: Method for substances touchy to time temperature records and/or moisture

ASTM D1238-2013 "Standard Test Method for Measuring Thermoplastic Melt Flow Rate by means of Extrusion Plastometer"

ASTM D3364-1999 (2011) "Polyvinyl chloride float price and feasible have an impact on on molecular shape size method"

JB/T5456-2016 "Technical Conditions of Melt Flow Rate Meter"

DIN53735,UNI-5640

Feature

1. The most important laptop computer is assembled by way of the use of separate sheet metal parts, the manipulate device and the heating furnace are separated, which greater protects the manipulate device from being affected by way of way of immoderate temperature and influences the life of the components. It is on hand to disassemble and assemble, spray-painted, and is neat and beautiful.

2. The barrel and piston rod are made of alloy materials with immoderate temperature resistance and low boom coefficient. The ground warmness remedy is used to make it non-deformable and immoderate in hardness at immoderate temperatures, and it is no longer common to put on beneath long-term use to make sure data accuracy.

3. The rotary encoder is used as the displacement measuring device, and the lever principle is used to make sure the the the front and rear balance without more gadgets such as springs, for this motive efficiently stopping dimension errors when measuring displacement.

4. Micro-motor managed cutting device, which can set the cutting time or decrease manually. The operation is simple. The cutting knife is made of high-strength spring steel to make certain that the equipment is now now not deformed or damaged when the equipment is minimize for a prolonged time.

5. The exhibit is a 7-inch contact screen. The interface is affluent in information, convenient and convenient, and can rapidly and exactly maintain shut the cutting-edge test status.

6. The CPU uses the world's advanced STM32 chip, 32-bit computing, computing speed is very fast (designed by British arm company). Users can choose whether to retain or no longer print the current test data according to their personal needs.

7. The dashboard retains different identification interfaces, which can be upgraded and used by users themselves in the later use.

8. The exhibition shows the modern American era. During the test, we are reminded of our current personality.

9. Humanized design: the backlight adjustment and key function in the notebook Settings meet the user's usual use habits and enhance practicality.

10. User Help: List common fault symptoms and user preferences.

11. English and Chinese can be switched at any time.

12. Each test result can automatically print a report, supporting both Chinese and English modes.

13. When the user manually turns off the temperature control system, the device will pop up a prompt whether the user will complete the cleaning of the equipment, which greatly reduces the damage caused to the equipment due to the user forgetting to clean the material, and can effectively protect the equipment and extend the service life.

Main technical parameter:

Measure range | 0. 01-600.00 g/10min (MFR) |

0. 01-600.00 cm3/10min(MVR) | |

Temperature range | 0-400℃ |

Temperature Fluctuation | ±0.2℃ |

Temperature gradient | ≤0.5°C (within 10~70mm of the upper end of the die in the barrel) |

Temperature resolution | 0.01℃ |

Measuring method | MFR MVR |

Material canister | Inner diameter : 9.55±0.007mm |

Inner length :160mm | |

Mould | Inner diameter: 2.095mm |

length: 8±0.025mm | |

Barrel temperature recovery time after feeding | ≤4min |

Displacement measure range | 0-30mm |

Displacement accuracy | ±0.02mm |

Displacement resolution | 0.01mm |

Timing accuracy | 0.01s |

Load | full load |

Base weight | (piston weight + base poise weight) 0.325Kg |

Weights (poise) | 0.875Kg, 1.290Kg, 1.835Kg, 3.475Kg, 4.675Kg,5.000Kg, 5.000Kg one each (may freewill combination ) |

Poise can be | 0.325Kg,1.0Kg,1.2Kg,2.16Kg,3.8Kg,5.0Kg, 10.0Kg,21.6Kg |

Poise Accuracy | ≤±0.5% |

Supply Power | AC220V±10% 50Hz |

Heat up power | 550W |

Dimension | 580×480×530 |

Weight | 110kg |

Packing list:

Item | Quantity |

Host | 1PC |

Base weight | 1PC |

Weight | 1unit (six sort’s seven pieces) |

Piston | 1PC |

Mould | 1PC |

Oriented sheath | 1PC |

Water level bubble | 1PC |

Hopper | 1PC |

Clean material pole | 1PC |

Mould bore | 1PC |

Material check | 1PC |

Product information

To determine the melt mass-flow MFR (g/Omin), the melt volume-flow rateMFV(cm3/0min) and the melt density of thermo resin,

for the engineering plastics ofpolycarbonate, nylon and fluorine plastics, whose melt temperature are higher, but also fitfor the plastics tests of polyethylene,

polystyrene, polypropylene, ABs resin andpoly-formaldehyde resin, etc, whose melt temperature are lower, widely applied to thefields of plastics materials,

product, petrochemical.

SIMPLE OPERATING SYSTEM

Large screen, clear at a glance, easy to operate

Product Size:580*480*530mm

PRODUCT CUSTOMIZATION

We can also customize the logo according to your requirements( if you have any requirements, please contact us in time, we will provide

you with the best solution)

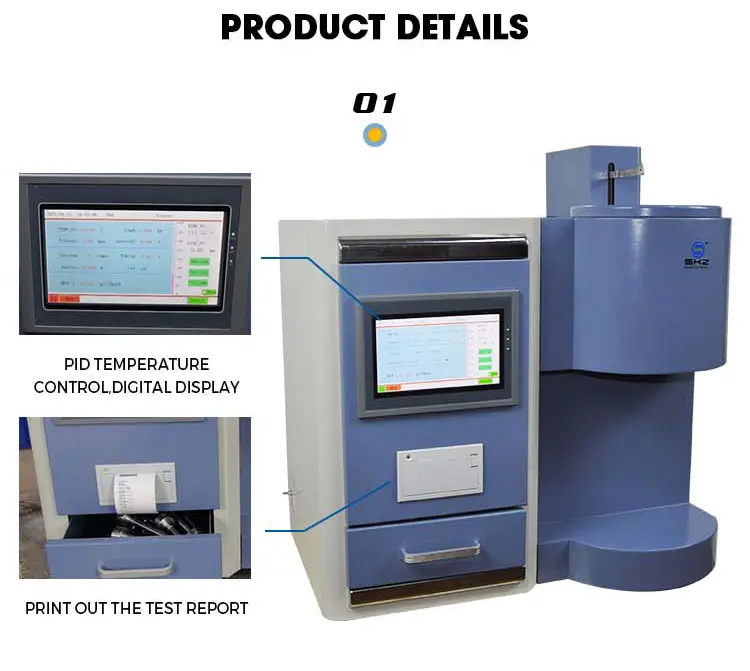

PRODUCT DETAILS

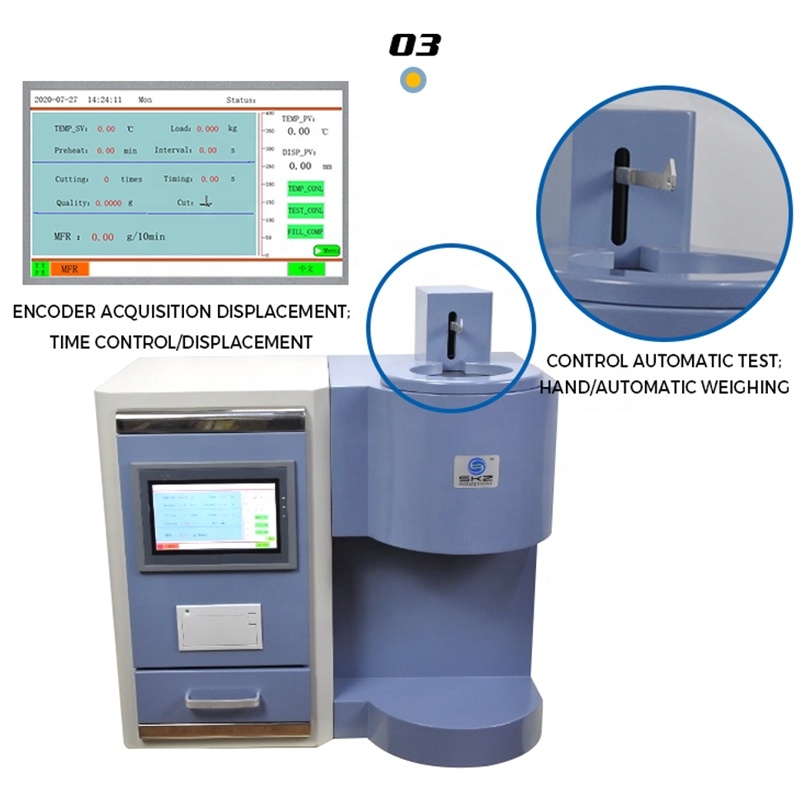

01

PID TEMPERATURECONTROL,DIGITALDISPLAY

PRINT OUT THE TEST REPORT

02

HAS TWOMEASURING METHOD MFR AND MVR

CUT MATERIAL AUTOMATICALLY

03

ENCODER ACQUISITION DISPLACEMENT;

TIME CONTROL/DISPLACEMENT

CONTROL AUTOMATIC TEST;

HAND/AUTOMATIC WEIGHING

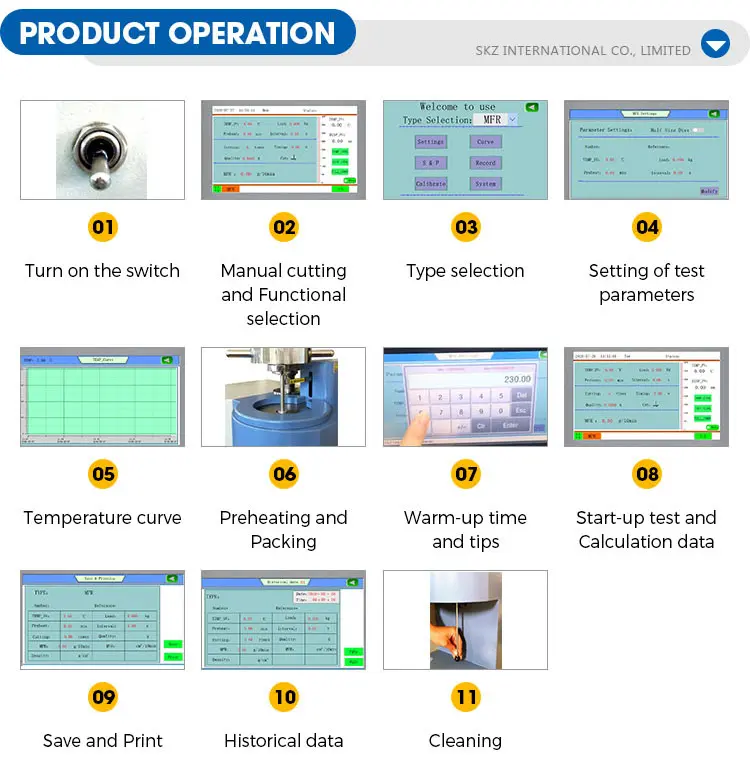

1: Turn on the switch

2: Manual cutting and functional selection

3:Type selection

4:Setting of test parameters

5: Temperature curve

6: Preheating and packing

7:Warm-ip time and tips

8: Start-up test and calculation data

9:Save and print

10:Historical data

11:Cleaning

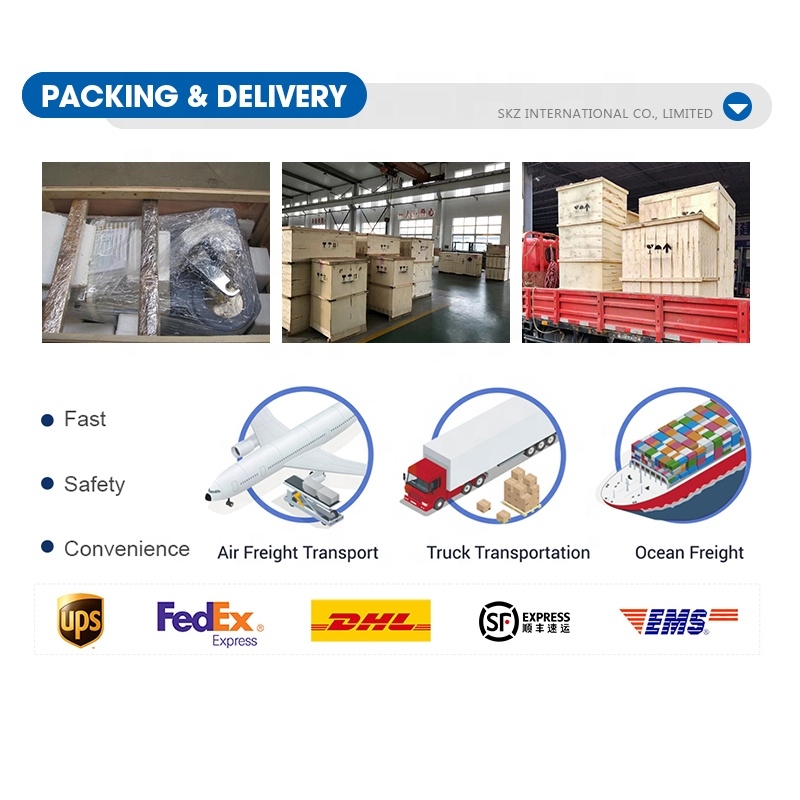

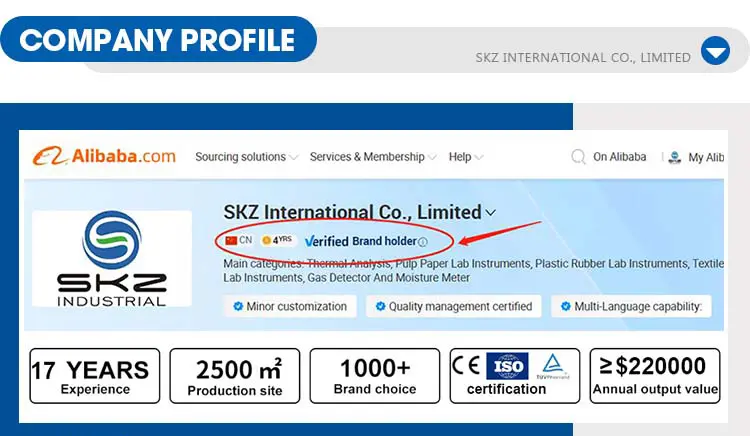

SKZ INTERNATIONAL CO., LIMITED

PROFESSIONAL PRODUCTION ADVANTAGE

SKZ Industrial Co., Limited and SKZ International Co, LTD are the members ofSKZ group, We are specialized in manufacturing and supplyLab equipment Sci-entific instrument, testing instruments for plastic and rubber. "SKZ" is the trademark, We passed the SGS/TUV inspection certification, CE certification and lSOcertification. SKZ is established in the year of2006, we can provide one-stop service with professional and prompt pre-sales, mid-sales, and after-sales support.With more than 16 years' experience in the field of Laboratory Instrument,we care about your laboratory, more concerned about your experience, you can find us 24 hoursseven days a week. Our products have been exported to America, the European Union, SoutheastAsia and Africa.

We welcome customers to contact us for future business relationships and mutual success!

Within a year, if there are quality issues,wecan provide free technical supportandrepair, as well as shipping costs

After one year, we still provide technical support free charge, includingsoftware update service.And if need to return repair,user need to bear therepair accessory charge and round-trip shipping costs.

WhatsApp/Cell: +8618678395869

Skype: +8618678395869

Wechat: +8618678395869