Digital Carbon Black Content Tester

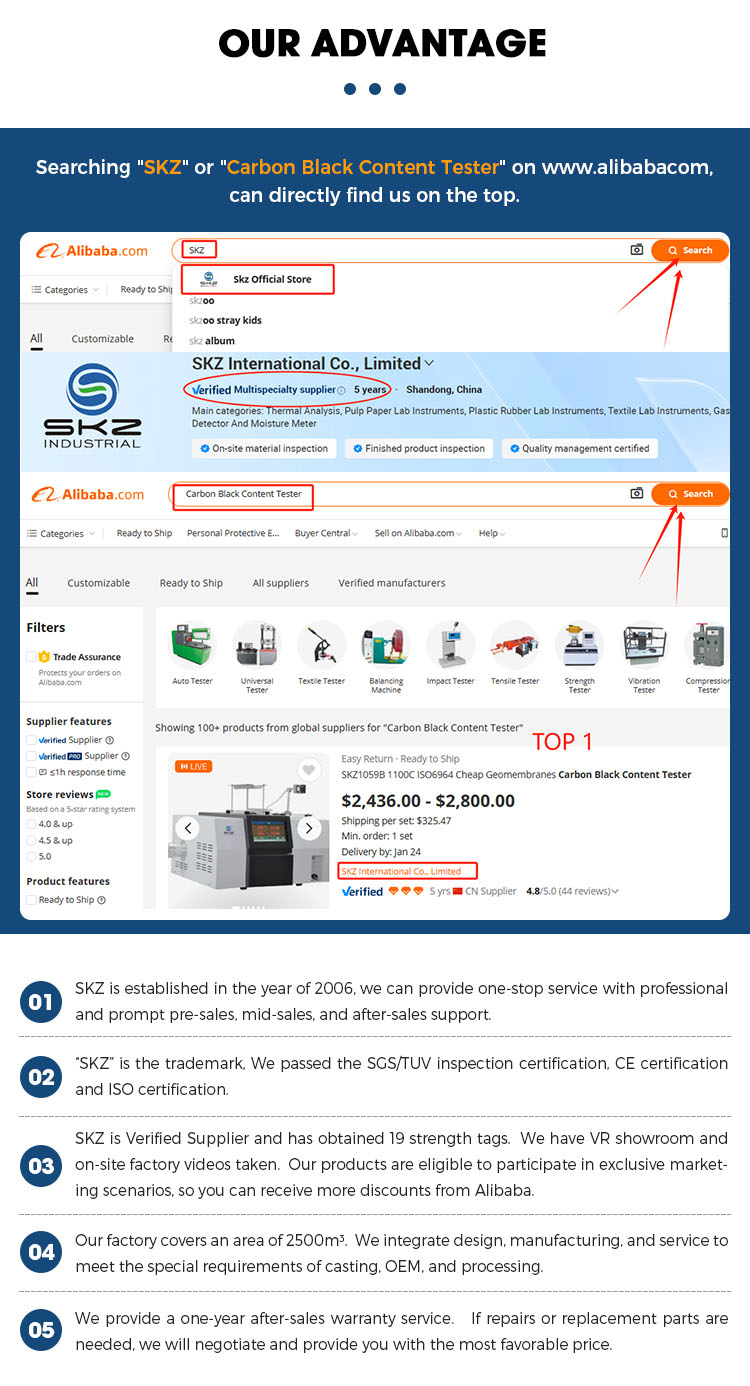

1.No need to open the sealing valve, without using other sampling tools to reduce errors and improve measurement accuracy.

2.uniform heat around the sample, the test accuracy is higher

3.using double-wire wound heating, heating more uniform, and anti-aging

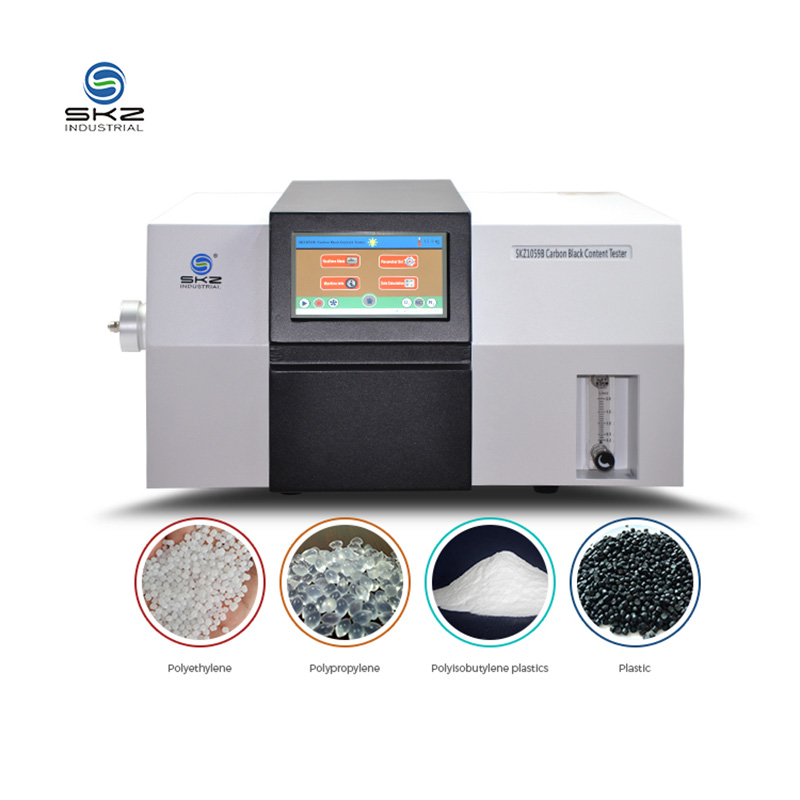

SKZ1059B Pyrolysis Plastic Carbon Black Content Tester Machine

It applies to polyethylene, polypropylene and polyisobutylene plastics in the dedication of the content material of carbon.

Standard :

ISO 6964: Determination for the carbon black content material of polyethylene pipes and fittings by means of calcination and pyrolysis

ASTM D1603: Test Method for Carbon Black Content in Olefin Plastics

IEC 60811-4-1: Common check strategies for insulating and sheathing substances of electric powered and optical cables—Part 41:Methods unique to polyethylene and polypropylene compounds—Resistance to environmental stress cracking—Measurement of the soften glide index—Carbon black

Features:

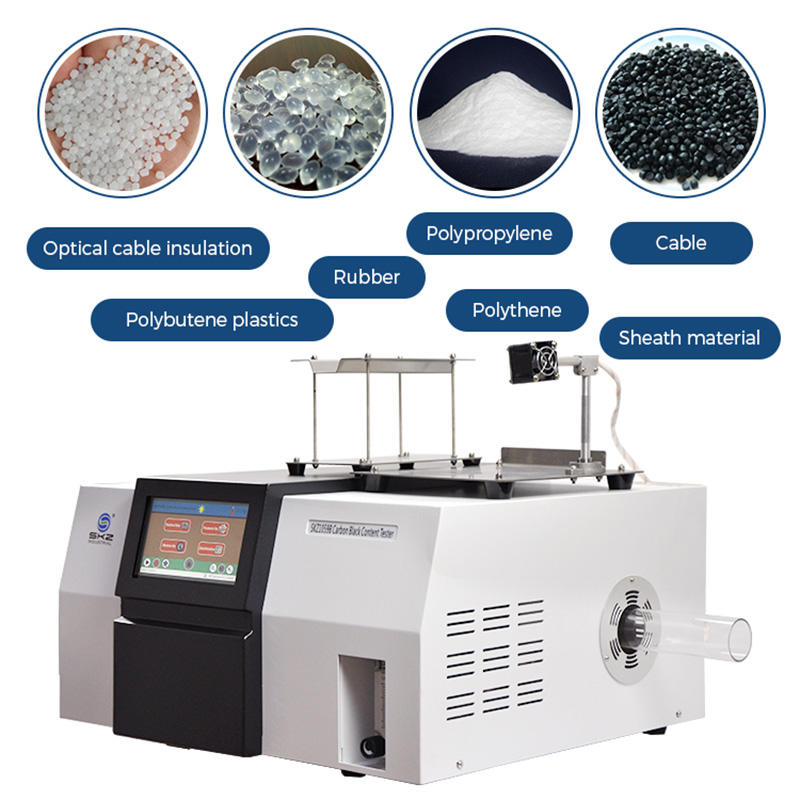

1. During the take a look at process, the samples had been taken and launched with a easy information rail. The information rails had been used to pull out the samples directly. No want to open the sealing valve, besides the use of different sampling equipment to minimize mistakes and enhance dimension accuracy.

2. Sample combustion boat information rail support, placed in the core of the heating furnace core location to make sure uniform warmness round the sample, the check accuracy is higher. Avoid the typical combustion boat positioned immediately on the take a look at tube, the drawbacks of uneven heating.

3. The injector for the pattern combustion boat is marked, scaled, and bespoke to make sure that the identical necessities are positioned on the pattern places in a repetitive test, simply as itis for every insertion into the furnace. The regular carbon black content tester, to make their very own mark, have a look at and then adjusted, main to low efficiency, terrible repeatability.

4. Avoid open-door furnace defects, the use of double-wire wound heating, heating greater uniform, and anti-aging.

5. During the test, the pattern can be cooled internally and geared up with impartial fan cooling to velocity up the cooling and enhance the cooling efficiency. Even if the pattern temperature reaches one thousand ° C, the exterior enclosure temperature is continually <50 ° C.

6. Atmosphere control, application switching, however additionally manually thru the contact display screen to swap to make the operation extra smart and greater convenient.

7. 7-inch high-definition capacitive contact screen, Real-time show of temperature curve. 50 part temperature can be set, A key calculation of carbon black content.

8. Exhaust give up can be outfitted with automated cleansing bottle, cleansing bottle customers can replace, however additionally via the instrument window to have a look at the fuel reaction.

9. Allow the resolution of a appropriate combustion crucible for trying out more than one samples.

Technical Parameters:

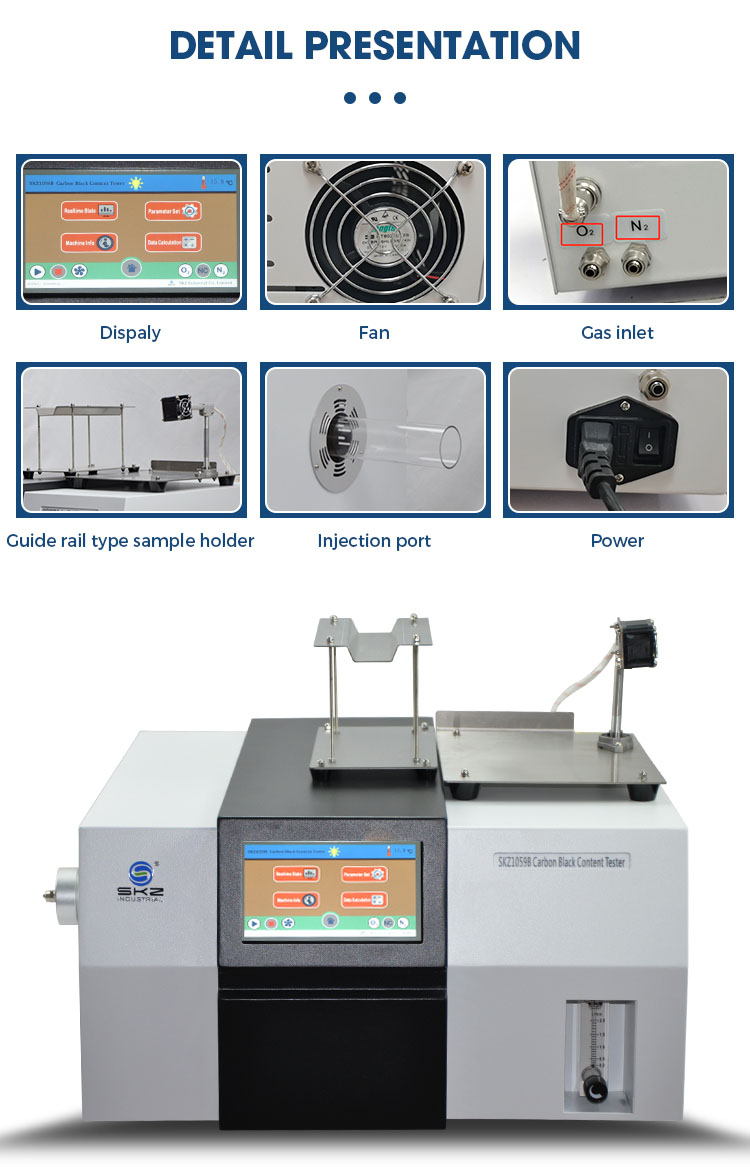

Display | 7-inch capacitive touch screen display |

Tube size | Ф45 × 450mm |

Heating element | high temperature nickel-chromium wire |

Heating area length | 300mm |

Temperature area length | 200mm |

Operating temperature | ≤ 1100 ℃ |

The maximum temperature | 1200 ℃ |

Temperature control mode | 50 programmable control |

Temperature accuracy | ± 0.5 ℃ |

Sensitivity | 0.1℃ |

Heating rate | 1℃ ~ 50℃ / min |

Power | ≤ 1KW |

Working voltage | AC220V / 50HZ / 60HZ |

Atmosphere | two paths |

Atmosphere switch | fully automatic |

Packing list:

Name | Model | Quantity |

Host machine | SKZ1059B | 1 set |

Furnace | 1 set | |

Burning boat | 10 | |

Power Cord | 1 | |

10A fuse | 5 | |

Sensor | 1 | |

Forceps | 1 | |

Hose | 1 m, 3 m | Each one |

stopper and glass tube | 2 sets |

It conforms to the national standard GBT 3515-2005, GBT 13021-1991. GB/T2951.41-2008

IEC60811-4-1: 2004. etc.

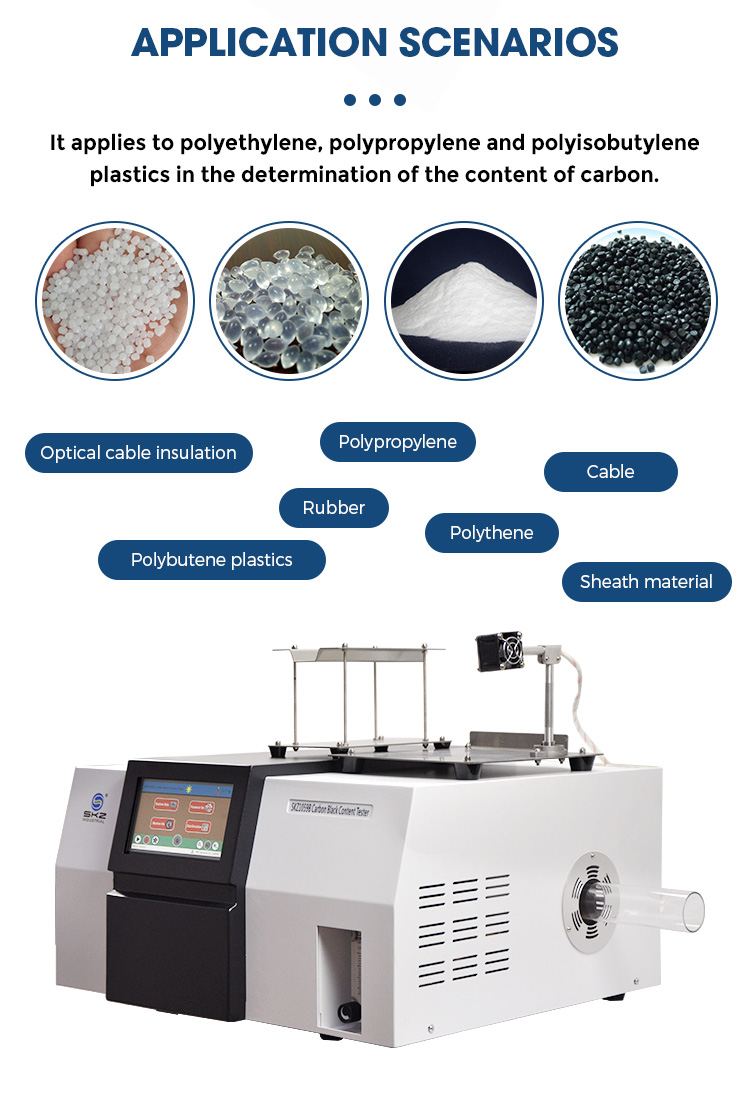

APPLICATION SCENARIOS

It applies to polyethylene, polypropylene and polyisobutylene plastics in the determination of the content of carbon.

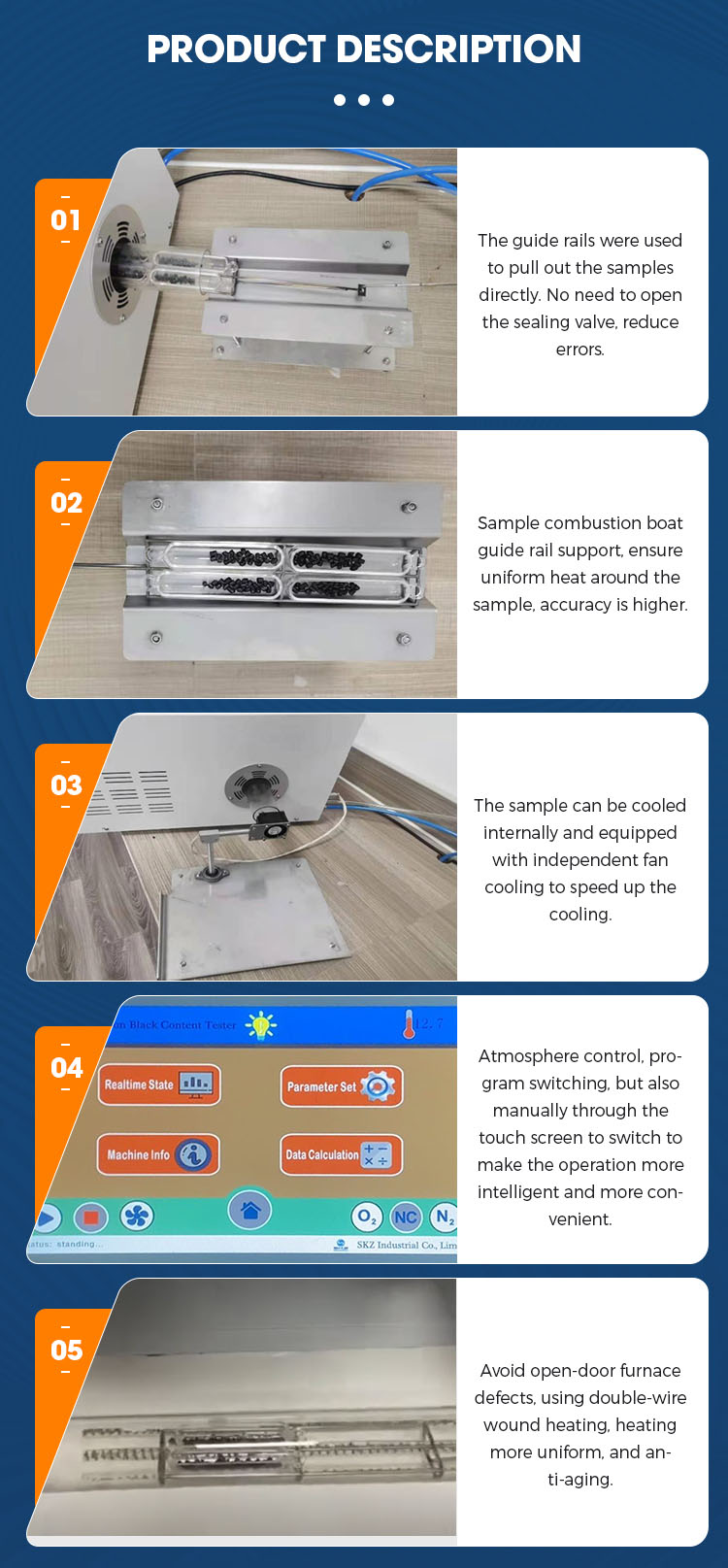

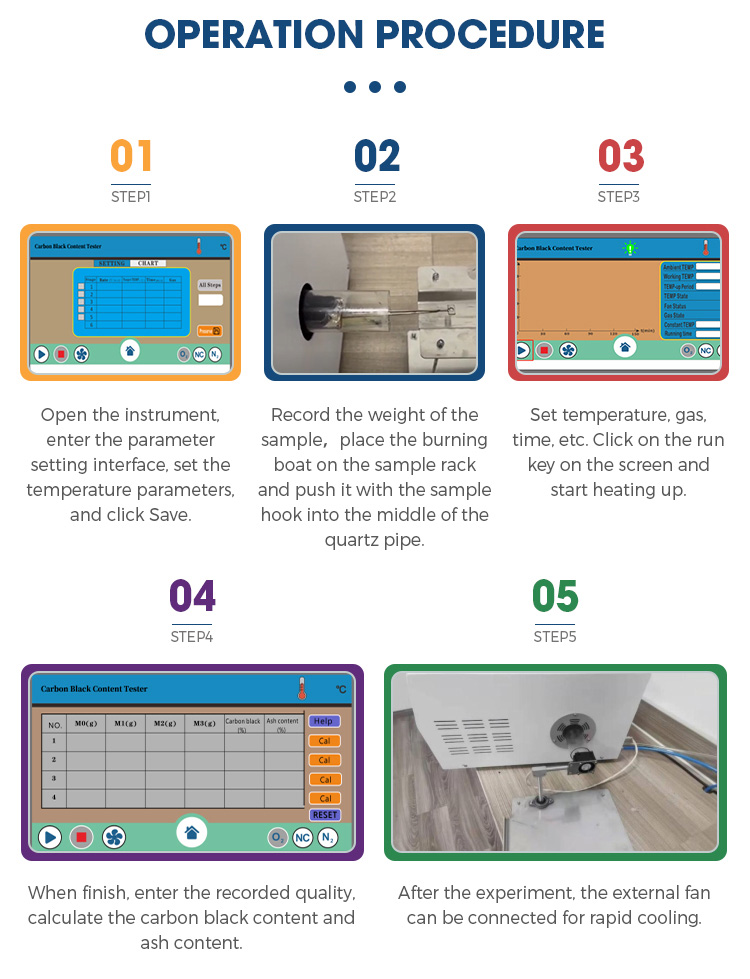

1. The guide rails were used to pull out the samples directly. No need to open the sealing valve, reduce errors

2. Sample combustion boat guide rail support ensure uniform heat around the sample, accuracy is higher

3. The sample can be cooledd internally and equippec with independent fan cooling to speed up the cooling

4. Atmosphere control, program switching, but also manually through the touch screen to switch to make the operation morel

intelligent and more con-venient.

5. Avoid open-door furnace defects, using double-wire wound heating, heating more uniform, and an-ti-aging

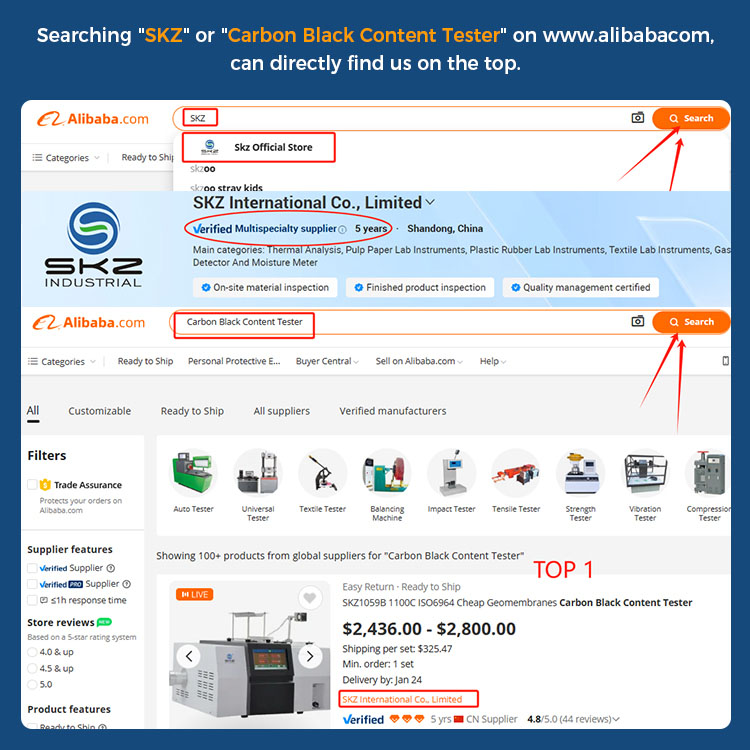

Welcome to contact me: sale7@skzindustrial.com

WhatsApp: +86 15508650267